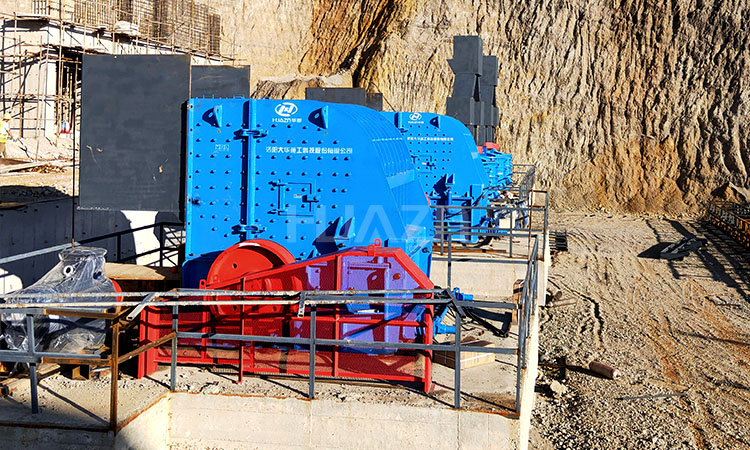

1000 TPH Basalt Crushing Site and Crusher Machine

The basalt crushing production line includes ZSW vibrating feeder, JC jaw crusher, GPY cone crusher, HPY cone crusher, PLS sand making machine, YKR vibrating screen and GZG feeder.

The basalt crushing production line includes ZSW vibrating feeder, JC jaw crusher, GPY cone crusher, HPY cone crusher, PLS sand making machine, YKR vibrating screen and GZG feeder.

Stone crusher is used for coarse crushing, medium crushing and fine crushing of 200+ rocks. The commonly used stone crushers are jaw crushers, cone crushers, impact crushers, mobile crushers, and VSI sand crushers. In this text, we will introduce the commissioning and test run of stone crusher machine.

Cone crusher is widely used in mining, construction and metallurgy industries for the medium and fine crushing of various medium and hard materials, such as mineral ores, basalt, granite, limestone, cobble and sandstone, etc. How to operate cone crushers?

The mobile crushing plant can break down large chunks of material into smaller pieces in the quickest most efficient way that are easily movable on and between production sites.

Stone crusher machine is the main crushing equipment in the stone crushing production line. Luoyang Dahua provides jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crushers. How to maintain stone crushers?

High efficiency cone crusher is widely used in mining, construction and metallurgy industries for the medium and fine crushing of various mineral ores, basalt, granite, limestone, cobble and sandstone.

When it comes to breaking various types of stones into those required for construction purposes, the selection of appropriate crushing equipment is important. With the focus on project cost and return, this article will thoroughly compare three mainstream crushing solutions - jaw crushers, impact crushers, and cone crushers.

Granite jaw crusher is mainly composed of main frame, fixed jaw and sewing jaw, driving structure, locking device, adjusting device and safety device. What's the function of these parts? Below is the detailed description of each component.

Impact crusher is mostly used crusher for crushing medium hardness stone, such as limestone, pebble, bluestone and so on. What are the advantages of impact crusher?

Crushing is the key step in the whole steel slag recycling treatment production line, which is mainly to crush and separate the steel slag through uniform feeding, coarse crushing, and medium crushing. Cone crusher is a commonly used equipment in steel slag treatment.