Can Cone Crusher Crush Quartz?

Modern cone crushers incorporate several design elements that make them particularly suitable for quartz. It adopts the technologies on crushing chamber optimization and combination of laminating and high-efficiency.

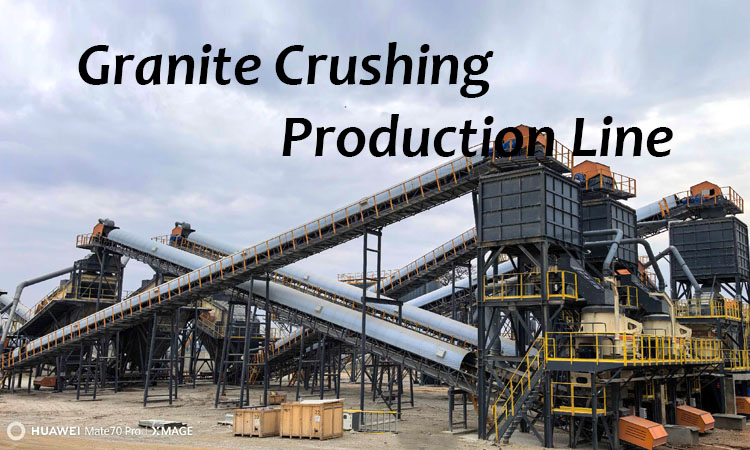

What Materials can Be Used to Produce Machine-Made Sand?

What raw materials can be used to produce machine-made sand? What equipment is needed? How much does it cost to invest in one set?

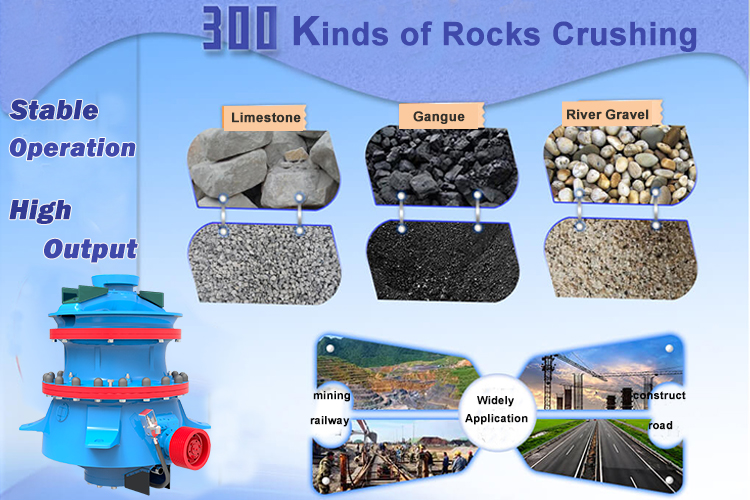

The Comprehensive Guide to Compound Crushers: Advantages and Selection Criteria

The vertical compound crusher is a high-efficiency piece of equipment that integrates fine crushing and coarse grinding into one unit. It is designed to process materials with a compressive strength no more than 200MPa, such as limestone, gypsum, clinker, coal gangue, and iron ore.

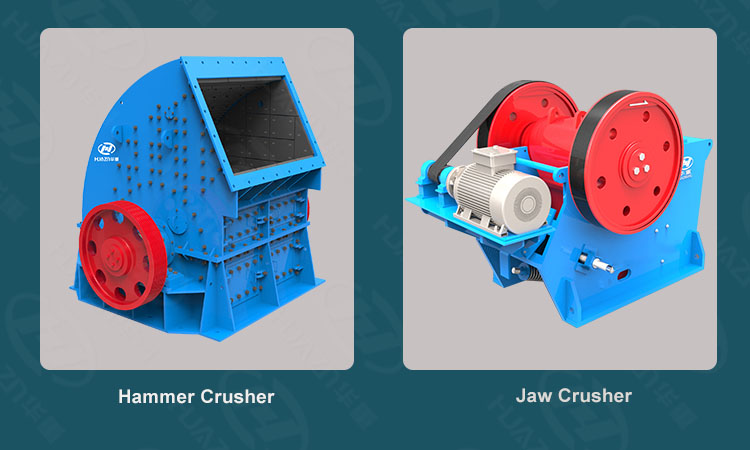

What are the Differences between Hammer Crusher and Jaw Crusher?

Hammer crushers and jaw crushers are both commonly used equipment. However, what are the differences between the two crushers?

Recycle Machine for Fine Sand in Construction Waste Treatment

XH Series Recycle Machine for Fine Sand is used to recycle part of fine sand (0.16mm or less) which is taken away by sand washing water in processing system (wetmethod) of fine sand for sand and aggregate production.

What is the Best Crusher for Dolomite?

Choosing the right crusher for dolomite is crucial to achieving the desired particle size, shape, and production efficiency. This article explores the types of crushers suitable for dolomite and provides insights into selecting the best one for your specific needs.

How Much Does a 50 TPH Ore Crusher Cost?

When considering the purchase of an ore crusher with a capacity within 50 tons per hour, one quickly discovers that the price is not a single figure but a range influenced by numerous factors. Luoyang Dahua sales manager will summarize from the costs, types, and key considerations for potential buyers.

A Comprehensive Analysis of Stone Crusher: How to Choose among the Three Main Models?

For aggregate processing, quarries, and mining, selecting the right primary, secondary, or tertiary crusher is a critical decision that directly impacts productivity, product quality, and operational costs. Jaw crusher, cone crusher, and impact crusher are the three main models.

Essential Equipment for Processing Construction Waste into Sand

Processing construction waste into high-quality sand requires a systematic approach and specialized equipment. Here’s an overview of the essential machinery needed for an effective construction waste-to-sand operation.