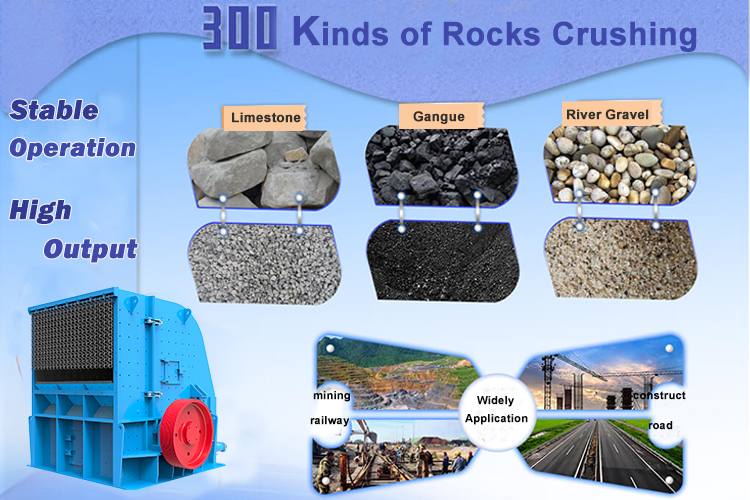

What Customers Focus on When Choosing an Impact Crusher?

Choosing the right impact crusher is a critical decision for quarry, mining companies, and recycling facilities. Based on frequent inquiries from our clients, we have compiled the key areas of concern and provided clear explanations to guide your selection process.

Price Analysis of Cone Crushers

There are numerous brands of cone crushers in the market, with varying quotations and complex intermediate links. How can one purchase the equipment with the best cost performance? As a direct sales manufacturer deeply engaged in the mining machinery field for decades, Luoyang Dahua today takes you through the confusion and answers one by one.

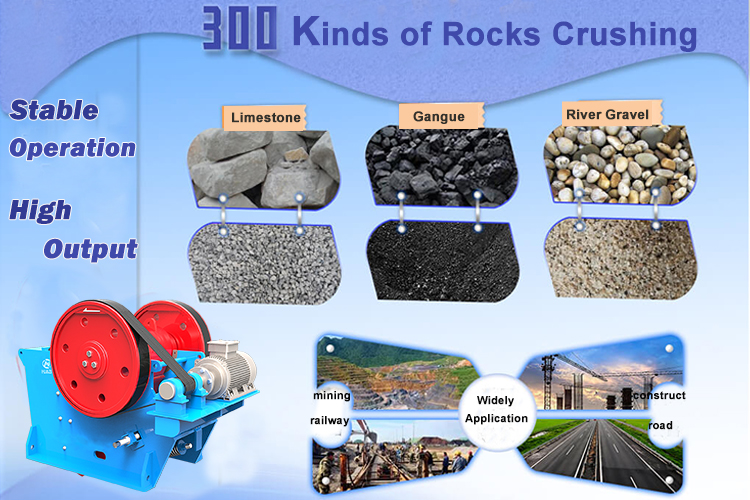

What should be pay attention to when purchase a jaw crusher?

Purchasing a jaw crusher is a significant investment for any quarry, mine, or recycling operation. It’s the heart of the primary crushing stage, and its performance dictates the efficiency of the entire downstream process. What should be pay attention to?

What makes the Price Variance of Sand Making Machine?

The price of sand making machine ranges from tens of thousands to hundreds of thousands US dollars. The price variance lies a huge disparity in equipment types, configuration, and sources. As a direct sales manufactures in mining machinery field, Luoyang Dahua will supply you high quality and cost-effective machinery and service.

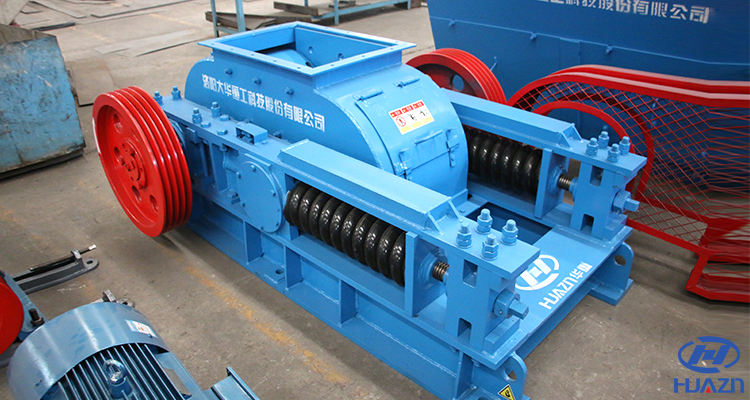

JC Jaw Crusher Production Capacity Range and Parameter

JC series jaw crushers with unique structure and superior performance, it is a type of preferable equipment for crushing various hard and highly abrasive rocks and minerals. Its production capacity ranges from 50 to 2000 tons per hour, which can meet the production demands of different capacities. It offers a wider range of choices and stronger applicability.

Complete Set of Stone Crushing Equipment and Price

Gravel is widely used in the fields of construction, road, water conservancy and other field, which is the indispensible material in the development of these fields. The gravels are processed from limestone, pebble stone, basalt, and quartz stone, with granularity of 5-31.5mm. What is the equipment for stone crushing? What is the price?

What are the Models of Small Coal Crusher? How much is One Set?

Small coal crushers are used to crush various types of coal and are applied in power plants, industrial boilers, construction, metallurgy and other fields. For small and medium-sized enterprises, small coal crushers can meet their production needs.

High-efficiency Fine Stone Crusher Machine Manufacturer

In the sand and gravel aggregate industry, how to produce finished materials with excellent particle shapes at a lower cost is the key to enhancing competitiveness. As an innovator in the medium and fine crushing field, the high-efficiency fine stone crusher is becoming an ideal choice to replace traditional equipment with its outstanding comprehensive performance.

New Crushing and Screening Equipment in Mining Industry

Cone crusher, gyratory crusher, jaw crusher, and mobile crushing station are the new crushing equipment in mining industry. Following is the detail introduction.