Crushing stone is a fundamental process in the construction and mining industries, producing materials used for roads, concrete, asphalt, and more. Stone crushing involves several stages, each designed to break down large rocks into smaller, usable aggregates. Here’s a detailed introduction about how stone crushing works.

- Primary Crushing (First Stage)

The process begins with large rocks extracted from quarries or mines. These raw materials are fed into a primary crusher, typically a jaw crusher or gyratory crusher, which reduces them into smaller, more manageable pieces (usually 6-12 inches in diameter).

Jaw Crusher: Uses compressive force with a fixed and movable jaw plate to break down stone.

Gyratory Crusher: Works similarly but with a conical head inside a crushing chamber.

- Secondary Crushing (Second Stage)

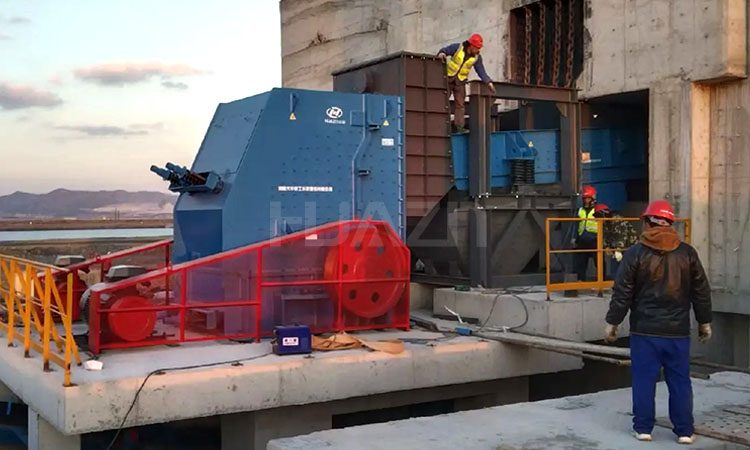

After primary crushing, the material moves to a secondary crusher, such as a cone crusher or impact crusher, to further reduce the size (down to 1-3 inches).

Cone Crusher: Crushes stone between a rotating mantle and a concave.

Impact Crusher: Uses high-speed impact forces to shatter stone.

- Tertiary Crushing (Optional Third Stage)

For finer materials, a tertiary crusher (like a vertical shaft impact crusher – VSI) may be used to produce sand-like particles (less than 1 inch). This stage is crucial for making high-quality concrete sand or railway ballast.

- Screening and Sorting

Crushed stone is then passed through vibrating screens to separate different sizes. Oversized material is sent back for further crushing, while correctly sized aggregates move to storage or final processing.

- Washing and Final Processing (If Needed)

Some crushed stone is washed to remove dust and impurities, especially for use in concrete production. A sand washing machine or spiral classifier may be used for this purpose.

- Stockpiling and Distribution

The final product is stockpiled based on size and transported for use in construction projects.

Stone crushing is a multi-stage process that transforms large rocks into various aggregate sizes for construction. Each stage—primary, secondary, and tertiary crushing—plays a crucial role in producing high-quality materials efficiently. Proper screening and washing ensure the final product meets industry standards, making stone crushing a vital operation in infrastructure development.