For aggregate processing, quarries, and mining, selecting the right primary, secondary, or tertiary crusher is a critical decision that directly impacts productivity, product quality, and operational costs. Its main application fields include:

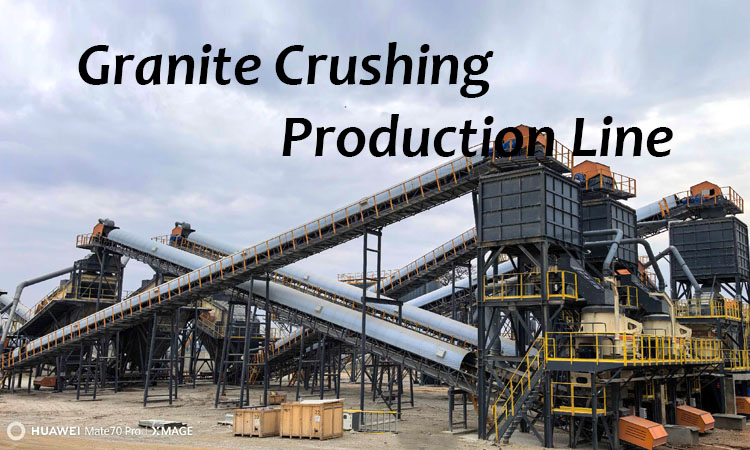

Sand and gravel aggregate production: Providing various specifications of crushed stones and manufactured sand for infrastructure such as construction, highways, railways, and bridges.

Mining: Coarse, medium and fine crushing processing of raw ores such as iron, gold, copper, limestone and granite.

Resource utilization of urban construction waste: Crushing discarded concrete, bricks, tiles, etc. into recycled aggregates, turning waste into treasure.

The preparation of raw materials for industries such as metallurgy, chemical engineering, and building materials.

Detailed explanation of the three main models of stone crushers.

Stone crushing is a systematic project. Different combinations of equipment are needed for different hardness, particle size and finished product requirements.

1. Jaw crusher – “Coarse Crushing Pioneer”, sturdy and durable

Positioning: Primary crushing stage, specializing in breaking tough rocks.

Advantages: Simple structure, reliable operation, convenient maintenance, large crushing ratio, and good at handling large raw materials (feed particle size up to 1200mm). It is the most economical and efficient choice for the initial crushing.

Application: Primary crushing of various high-hardness ores and rocks.

2. Cone Crusher – “Master of medium and fine Crushing”, highly efficient and energy-saving

Positioning: Medium and fine crushing, particularly for high hardness raw materials.

Advantages: By the use of laminating crushing principle, the cone crusher has large capacity, low energy consumption, small abrasion, and smooth operation. The finished product has good shape, low content of needle-like particles. The hydraulic adjustment and cavity clearing function, making the operation more intelligent.

Applicable to: Secondary and tertiary crushing of medium and high hardness materials such as granite, basalt, river pebbles and iron ore.

3. Impact Crusher – “Shaping Expert”, with outstanding particle shape

Positioning: Medium and fine crushing, particularly skilled in handling medium and low hardness materials and optimizing particle shapes.

Advantages: The crushed finished particles are cubic in shape, with a reasonable gradation, good appearance and high value. The equipment has both crushing and shaping functions, with a compact structure and is easy to maintain.

Applicable to: Crushing and shaping of medium and low hardness materials such as limestone, concrete, and construction waste. It is a commonly used equipment for manufactured sand and high-quality gravel.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.