With the rapid development of infrastructure and real estate, the market demand for manufactured sand has been steadily increasing. As a key component of sand and gravel production, the equipment configuration of a sand-making production line should be flexibly adjusted based on production capacity, raw material characteristics, and investment budget. Considering the latest market demands, this article presents optimized equipment configuration plans for sand making production lines and includes an analysis of investment costs, offering practical guidance for investors of different scales.

I. Core Equipment and Process of Sand-making Production Line

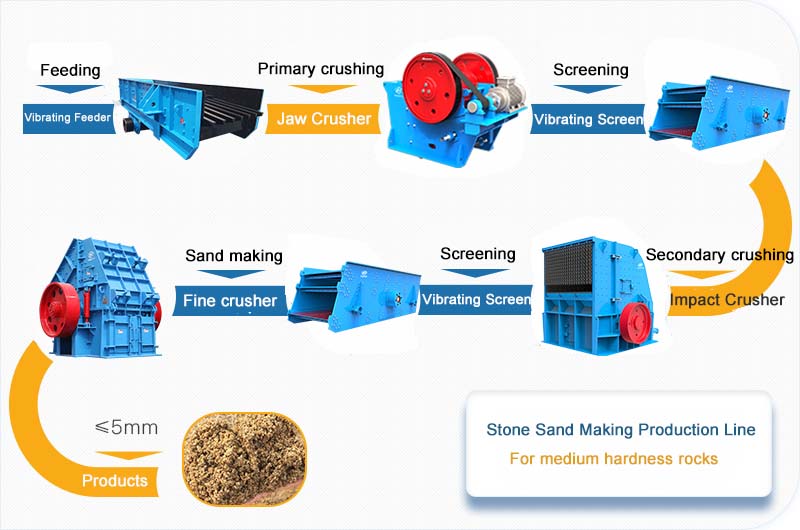

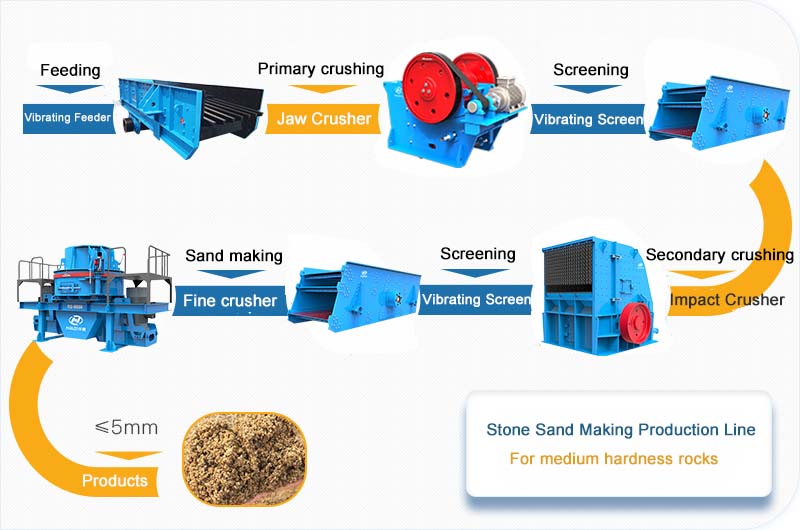

A complete sand-making production line usually includes the following equipment

Feeding equipment: Vibrating feeder, responsible for evenly conveying raw materials to the crusher.

Coarse crushing: Jaw crusher (for processing raw materials with high hardness and large size).

Medium crushing: impact crusher/cone crusher or mobile crusher (flexibly adapted to different scenarios).

Sand-making equipment: vertical shaft impact crusher, hammer crusher (select according to the requirements of the finished sand).

Screening equipment: vibrating screen(for grading and screening finished products of different particle sizes).

Sand washing equipment: bucket wheel sand washing machine or spiral sand washing machine (to improve the cleanliness of sand materials)

Auxiliary equipment: belt conveyors, dust removal devices, electrical control systems, etc.

Production process: Raw materials → coarse crushing → medium crushing → sand making → screening → sand washing → finished product storage.

II. Analysis of Investment Cost Composition

The total investment cost of the sand-making production line mainly includes

Equipment procurement (accounting for 60%-70%) : The cost of mobile crusher is higher than that of fixed crusher, but it can save infrastructure costs.

Infrastructure costs (10%-15%) : Mobile production lines require only a simple site for operation, whereas fixed production lines involve the construction of a dedicated factory building.

Operating costs: Electricity, labor, replacement of vulnerable parts (such as jaw plates, mantle, concave, etc).

Environmental protection investment: Dust removal and noise reduction facilities are available, with an additional budget required for regions that have mandatory requirements.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.