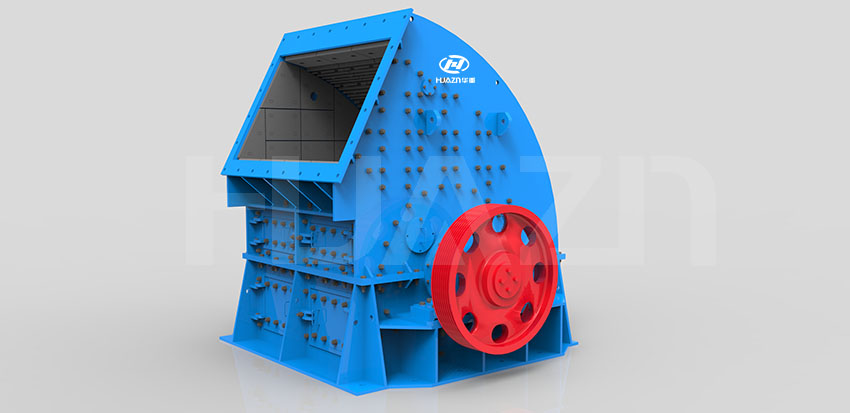

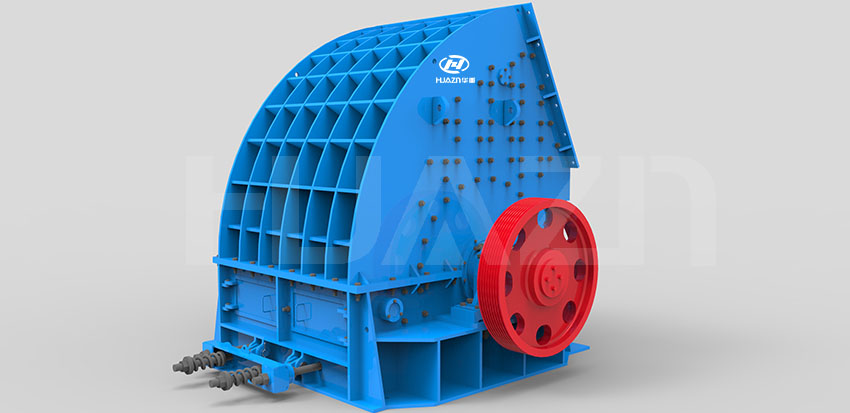

PCZ Series Hammer Crusher

Max. Feed Size: 750-1500(mm)

Processing Capacity: 250-2000(t/h)

Application Fields: cement, construction, chemical industry.

Applied Material: Sand and gravel yard, concrete sand making, dry powder mortar, machine-made sand, power plant desulfurization, quartz sand, etc.

Tel.: +86 13938852499 E-Mail: lydhchina@huazn.com

Overview

PCZ series hammer crusher is mainly used for crushing stone in the building materials industry, road and railway construction, and other industries that use stone. It is suitable for crushing various materials with medium hardness and low hardness. It has the characteristics of unique structure, simple operation mode, high efficiency and energy saving, good product shape, adjustable discharge particle size, and cost saving.

Product Features

1.It can realize large crushing ratio(generally 10-25, the highest up to 50), convenient adjustment of discharge particle size, and reasonable gradation of finished materials; no grate design, no material blocking.

2.Reliable over-iron and overload protection, the elastic device of the adjustment part has a buffering effect.

3.The weighted rotor improves the reliability and moment of inertia of the rotor, and improves the processing capacity of the crusher.

4.The design of the volute, the ribs on the back, the internal and external impacts are strong, the body is strong, and the impact resistance is not deformed.

5.High chromium compound hammer head, long life, eight hammer holes, four spare.

6.The wear-resistant retaining ring fixed by the circlip pin is adopted, which is easy to replace, reduces labor intensity and increases start-up time.

Working Principle

Hammer crusher mainly relies on impact energy to complete the crushing operation of materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher chamber evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame. At the lower part of the rotor, there is a sieve plate. The particle size of the crushed material smaller than the sieve hole size is discharged through the sieve plate, and the material larger than the sieve hole size is retained in the sieve plate. Continue to be hit and ground by the hammer until it is crushed to the required discharge size and finally discharged out of the machine through the sieve plate.

Technical Parameter

| Rotor (mm) | Feeding port size (mm) | Feed size (mm) | Capacity(t/h) | Powder(kW) | |

| diameter x length | |||||

| PCZ-1512 | Φ1500×1160 | 1280×1060 | ≤750 | 250-320 | 160×2 |

| PCZ-1615 | Φ1660×1550 | 1580×1350 | ≤1000 | 400-600 | 250×2 |

| PCZ-1620 | Φ1660×2010 | 2080×1280 | ≤1000 | 700-1000 | 400×2 |

| PCZ-1820 | Φ1850×2010 | 2080×1280 | ≤1000 | 2800-1200 | 450×2 |

| PCZ-2125 | Φ2150×2490 | 2600×1680 | ≤1500 | 1200-2000 | 630×2 |

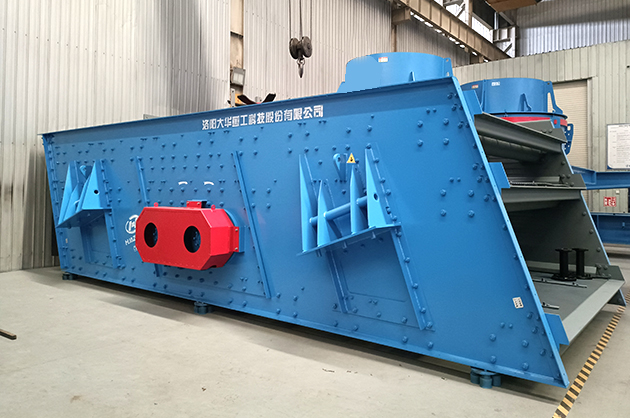

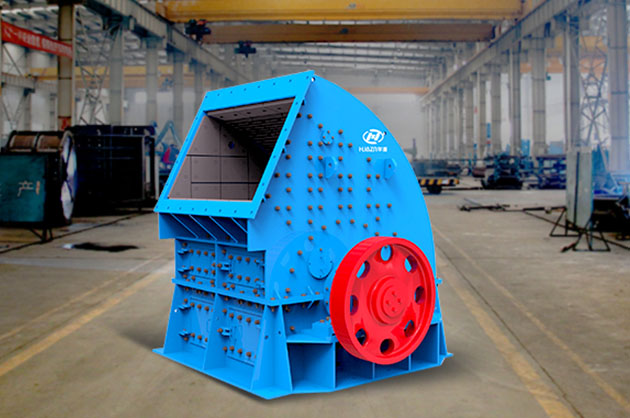

Customer Cases