Coal gangue is solid waste discharged during coal mining and coal washing. Its main components are Al2O3 and SiO2. It is a dark gray rock with lower carbon content and harder than coal, with a hardness of 3. If it is not used, it will occupy a large area of land, where sulfide escape or leaching will pollute the atmosphere, farmland and water bodies. These seemingly useless coal gangues can become sand after a series of processing and are made by sand making equipment. The finished product after sanding has better adhesion and compression resistance, and can be used in the field of building aggregates, road construction, etc., mainly in the fields of coal slag, brick factory raw materials, recycled bricks, building materials, etc. It is used as a base material for road paving in the field of road construction, and the effect is relatively good.

The production process of coal gangue sand is mainly composed of feeding, coarse crushing, medium and fine crushing, sand making, sieving, conveying and other links, which can be divided into fixed production lines and mobile production lines. Common equipments include vibrating feeders, vibrating screens and belts Conveyor, jaw crusher, impact crusher, sand making machine and other equipment.

Process and equipment:

Equipment at the initial breaking stage: jaw crusher + vibrating feeder

The initial breaking process is: the vibrating feeder directly and uniformly feeds large pieces of coal gangue to the jaw crusher. After the material is crushed by the jaw crusher, it is discharged from the discharge port through the discharge port, and then delivered to the medium and fine crushing processing section by the belt conveyor.

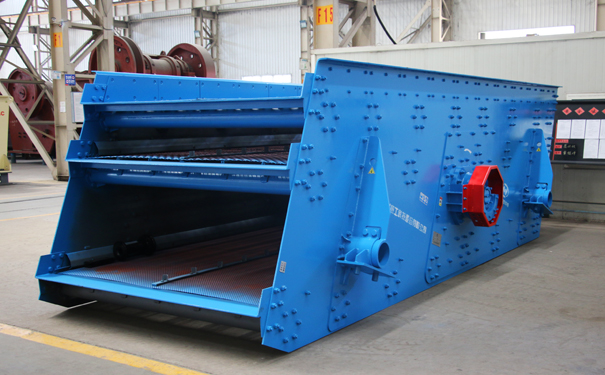

Equipment in the middle and fine crushing stage: impact crusher + vibrating screen

The medium and fine crushing process is: the coarse broken coal gangue scrap is directly fed to the impact crusher by the belt conveyor. The material is crushed by the impact crusher and then crushed again and then goes out through the discharge port, and then brought to the vibrating screen by the belt conveyor. The separated material is divided into two directions. The large-granularity returns to crush and then break, and the small-granularity is directly transported to the sand making section.

Equipment for the sand making stage: sand making machine + vibrating screen

The sand making process is: after the second fine crushing, the coal gangue stones are directly fed into the inlet of the sand making machine by the belt conveyor, and the sand making machine further processes it (fine crushing and reshaping), and the output particle size is below 5mm. Coal gangue sand with uniform particle size.

If you need sand washing, you can buy sand washing machine and fine sand recycling machine according to your needs.

At present, there is a shortage of natural sand, the government restricts mining, and there is a shortage of aggregates in the sand and gravel industry. Artificial sand and gravel can fill the gap in construction sand. Sand made from coal gangue is a waste reuse, with wide resources and low cost. The finished product has better adhesion and compression resistance. The processing of coal gangue into sand for building aggregates and road construction can't be better. It not only solves the problem that coal gangue will pollute the environment, but also fills the gap of sand and gravel aggregates. It has high economic, environmental and social benefits! The process of coal gangue sand production line is as described above, but there are different ways to match and combine, and the prices are also different. Users need to choose the appropriate sand production line according to their actual needs.