Sand making machine equipment is the key equipment of the sand making production line. Whether the finished aggregate can be sold at a good price in the market depends on the performance of the sand making machine. So, at present, how to choose the right sand making equipment? First of all, we have to consider what equipment is needed for a complete sand production line? At present, most of the sands on the market are cobblestone, limestone, granite, basalt, and construction waste. Sand making is generally divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by impact crusher or cone crusher, and sand making and shaping by sand making machine. Take granite as an example to introduce the sand making process.

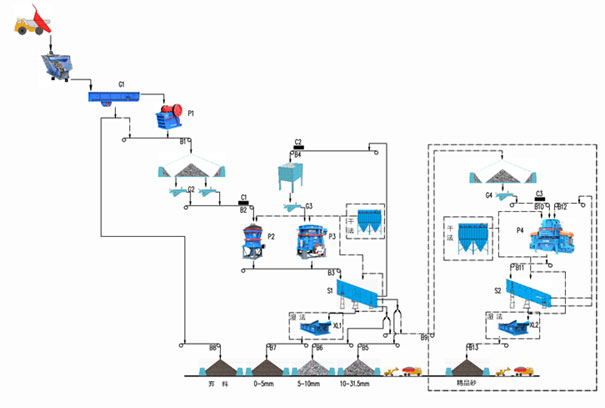

The first stage: the raw materials are coarsely crushed. Large ore is fed uniformly by the vibrating feeder through the silo, and then transported to the jaw crusher for coarse crushing. After the coarsely crushed ore is screened by the vibrating screen, it is transported by the belt conveyor to the impact crusher or cone crusher in the process of fine crushing.

The second stage: the ore conveyed to the impact crusher/cone crusher for medium and fine crushing is sieved by a circular vibrating screen, and the ore with larger particles is returned to the impact crusher/cone crusher for crushing again.

The third stage: sand making. The crushed ore is sent to the sand making machine for further crushing and shaping. The sand is screened and classified with a vibrating screen. If high-quality, clean ore is required, it can be sent to the sand washing machine for cleaning.

Which sand making machine is the core equipment of the sand production line?

Everyone knows that granite is a kind of hard natural sandstone. This kind of sandstone is harder than ordinary sandstone, but this is nothing to PLS sand making machine because of its unique performance and super strong. The processing capacity makes it easy to crush the granite material, and the finished material has a reasonable gradation and uniform particles. It can also be used in a high speed mode of 80 m/s or more for the fine crushing and shaping of the material to optimize the particle size of the finished product. At the same time, it also brings great convenience to the later screening. The work efficiency of the granite sand making machine is high. The equipment adopts professional technology and high-quality materials in all aspects. Therefore, the service life of the sand making equipment is also increased, and the structure is reasonable and simple. It is also the operation and maintenance of the granite sand making machine. It is more convenient, and this unique advantage also allows users of sand making machine equipment to save a lot of cost.

1. Deep cavity rotor design, the crushing cavity is deeper, the material throughput is larger, and the sand making efficiency is improved, while the river pebbles can fully collide with the broken wall in the crushing cavity, and the river pebbles can collide with each other, more broken and less ground, Improve sand formation rate, reduce powder content, and better sand making effect.

2. Hydraulic lid opening device. The thin oil lubrication scheme adopts hydraulic lid opening device. During Nissan work, users can directly open the lid for maintenance, which is easy to maintain. The thin oil lubrication scheme is used to effectively protect the sand making machine from overflow in normal operation. Green production is realized in the whole process, and the noise is relatively low, and does not interfere with the surrounding environment.

3. The air flow in the vortex cavity is self-circulating, and there is less dust leakage. There is no air flow in the vortex cavity. Generally, all kinds of dust will not overflow. Green production is realized in the whole process, and the noise is relatively low and does not interfere with the surrounding environment.

4. The wearing parts have good wear resistance and long service life. The wearing parts of the whole machine are on the throwing head, and the throwing head is also designed with high-quality steel. The overall design is combined, with better wear resistance and relatively long service lifelong.