Basalt is a good raw material for the production of "cast stone". "Cast stone" is a material made by melting, casting, and crystallization and annealing of basalt. It is harder and more wear-resistant than alloy steel. Basalt is also used as a "lubricant" in an advanced steel casting process, which can extend the life of the casting film. At the same time, basalt can also be drawn into glass filament, which is stronger in alkali resistance than ordinary glass filament cloth and has better high temperature resistance. Basalt has the advantages of strong compression resistance, low crushing value, strong corrosion resistance, and good asphalt adhesion. It has been recognized internationally as a good material for the construction of roads, railways, and airport runways.

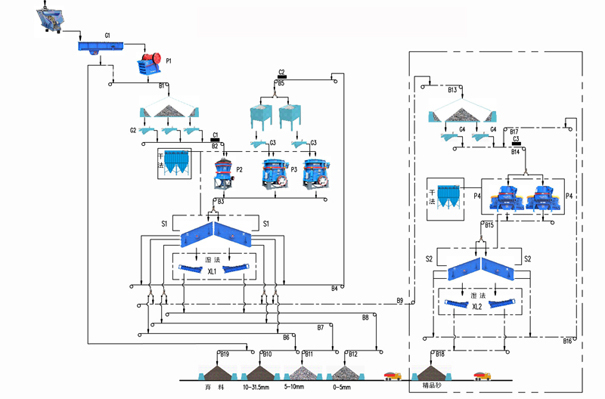

Basalt processing process: the processing of basalt is divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by impact crusher or cone crusher, and sand making and shaping by sand making machine.

Coarse crushing stage: the coarsely crushed basalt bulk material is uniformly fed by the vibrating feeder through the silo, and then transported to the jaw crusher for coarse crushing. After the coarsely crushed material is screened by the vibrating screen, it is transported to the belt conveyor the impact crusher or cone crusher is in the process of fine crushing.

Medium and fine crushing stage: The basalt transported to the impact crusher/cone crusher from the medium and fine crushing process is sieved by a circular vibrating screen, and the larger particles are returned to the impact crusher/cone crusher and crushed again.

Shaping and washing stage: The crushed basalt is sent to the sand making machine for further crushing and shaping. If clean basalt is needed, it can be sent to the sand washing machine for cleaning.

Screening and grading stage: the cleaned sand is screened and graded through a vibrating screen, and the sand of different gradations is dried and stacked for storage.

Are the cone crusher and impact crusher used in the middle crushing stage?

The HPY multi-cylinder hydraulic cone crusher is a high-performance crusher, which is mainly used in the second and third stages of crushing in metal mines and construction sand and gravel processing. Because of its strong crushing capacity and large output, it is more used for the crushing of medium-hard materials. The impact crusher can handle various coarse, medium and fine materials (granite, limestone, concrete, etc.) with side length not exceeding 600mm and compressive strength not exceeding 350MPa. It is widely used in various ore crushing, railway, highway and construction industries production of artificial sand and gravel.

Basalt is a material with relatively high hardness, which can damage the equipment. The cone crusher adopts the principle of laminated crushing, which has stable operation ability, high wear resistance of wear parts, and intelligent control system, which can crush materials with high hardness. The impact plate of impact crusher is easy to damage, generally for materials with low hardness. Generally speaking, the cone crusher is relatively suitable for basalt crushing, and the impact plate is replaced frequently in the later stage of the impact crusher.