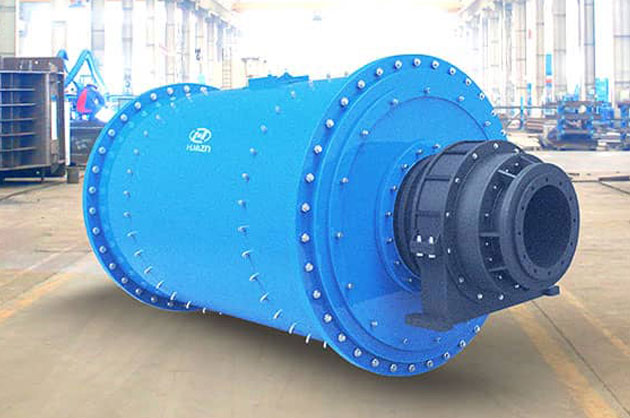

The ball mill is mainly responsible for the grinding operations of the beneficiation plant. It is a key link in the beneficiation process and accounts for a large proportion of the capital investment and production costs of the entire beneficiation plant. At the same time, the ball mill is also the “bottleneck” operation link of the entire concentrator. It is directly related to the overall processing capacity of the concentrator and has a major impact on the economic and technical indicators of the entire concentrator. Therefore, ensuring that the output of the ball mill meets the standard is the top priority.

In the production of the dressing plant, it is a very common problem that the output of the ball mill does not meet the design requirements, so under what circumstances will the output of the ball mill fail to meet the standard?

- Unreasonable design of the length ratio of each warehouse

The unreasonable ratio of the length of each bin of the ball mill will cause the unbalance of the coarse and fine grinding capacity of the ball mill, resulting in the phenomenon that the product is too coarse or too fine, and then affects the output. - The ball mill is not well ventilated

In the normal operation of the ball mill, due to the repeated impact and friction of the medium in the cylinder, the temperature in the mill continues to rise, causing water vapor to be generated from the water-bearing materials. If the ball mill is not well ventilated, the water vapor cannot be discharged in time, and the water vapor will adhere to the ball mill liner and steel balls cause paste ball or paste grinding phenomenon. Therefore, it is necessary to control the ventilation of the ball mill, and the passing effect of the ball mill is good, which can not only bring out qualified fine materials in time, but also effectively reduce the phenomenon of over-crushing and reduce the temperature of the ball mill. - Unreasonable feeding of ball mill

During the operation of the ball mill, uniform feeding is a necessary condition to ensure the normal operation of the ball mill. If the feeding is too small, the impact of the steel balls of the ball mill will increase, resulting in media waste; if the ball mill feeds too much, the grinding capacity of the ball mill will be insufficient. Resulting in saturation, so it is necessary to strictly follow the feeding standard for feeding. - The particle size of the ball mill is too large

The particle size of the ball mill is too large, and the impact and action of the grinding body are difficult to adapt. The first chamber of the ball mill will be broken to increase the amount of steel balls to enhance the impact and grinding ability. This situation is likely to cause unreasonable crushing in one chamber condition. - The water entering the ball mill is too large

When the water content of the grinding material of the ball mill is large, the grinding body and the liner will stick, which will cause paste grinding, block the grate plate, and cause the phenomenon of full grinding. But containing a small amount of water can effectively reduce the temperature of the ball mill and reduce static electricity. Therefore, the average water content of the ball mill is generally controlled at <15%. - The steel ball grading of the ball mill is unreasonable

Ball mill steel ball grading is to achieve the impact and grinding of materials with different particle sizes to improve the grinding efficiency. Therefore, the grading of ball mill steel balls is very important. The general grading range is between 25% and 35%, but in practical applications, the grading the majority is 28%~32%. - The temperature of the material entering the ball mill is too high

Generally, when the temperature of the input material of the ball mill is too high, it is easy to reduce the grinding efficiency. When the temperature of the ball mill exceeds 100°C, the air film isolated between the small particles of the material will be destroyed, causing adhesion. In order to reduce the temperature in the mill and improve the efficiency of milling, a small amount of mist-like water can be sprayed into the milling bin to lower the temperature in the mill to below 50°C.