Iron Ore Crushing Production Line

Processed material: Iron ore, copper ore, zinc and lead ore, pebbles, etc.

Crushing process: 3 stage crushing process. Crushing process + grinding process + separation process

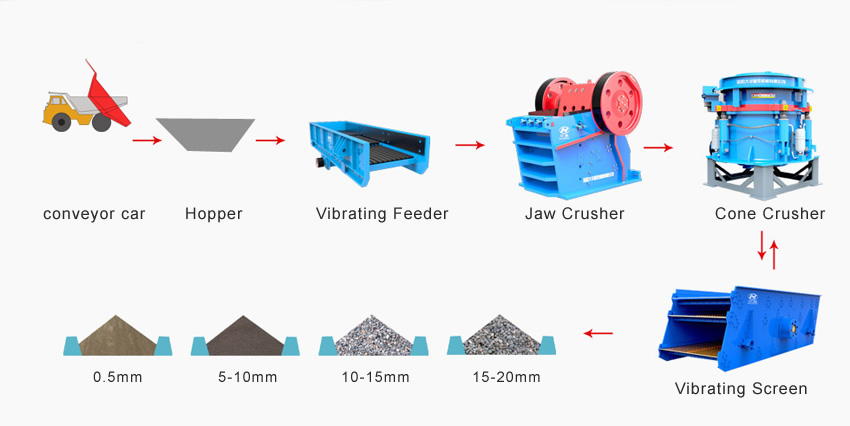

Dolomite crusher: jaw crusher, cone crusher, vibrating screen, belt conveyor.

Iron Ore Crushing Production Line Introduction

The iron ore crushing production line has the feature of high automation, high crushing ratio, low operation cost, energy saving and fine granularity. The production capacity is 20-1000 t/h. According to the specific production requirements, Luoyang Dahua Industry can offer you the comprehensive production line solution and technical support to meet your demands.

The iron ore crushing production line has the feature of high automation, high crushing ratio, low operation cost, energy saving and fine granularity. The production capacity is 20-1000 t/h.

Iron Ore Crushing Production Line Process

The iron ore is evenly fed into the vibrating feeder, which then uniformly delivers it to the jaw crusher. In the primary stage, the jaw crusher breaks down the stone before transferring it to the cone crusher for secondary crushing. Subsequently, the crushed material undergoes grading by a vibrating screen, with any substandard material being returned to the cone crusher for further crushing. Finally, qualified finished products are graded once again using a vibrating screen and subsequently transported to the finished product area through a belt conveyor.

The iron ore is uniformly delivered to the jaw crusher. In the primary stage, the jaw crusher breaks large iron ore into small particles, and then send to cone crusher for secondary crushing. Subsequently, the crushed material undergoes grading by a vibrating screen, any substandard material being returned to the cone crusher for further crushing.

Related Products

Max. Feed Size: 720-1360 mm

Production Capacity: 55-1500 t/h

Max. Feed Size: 35 – 560 mm

Production Capacity: 45-1200 t/h

CSS: 6 – 51 mm

Production Capacity: 60-2500 t/h

Max. Feed Size: 30-60 mm

Processing Capacity: 24-715 t/h