Gyratory crusher has many advantages such as high productivity, low power consumption, smooth and convenient operation, flexible working and high continuous operation rate. Especially in recent years, it has been widely used in mining industry for high tonnage applications.

Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material, which is suitable for large production plants and mining sites. According to experience, if the selection, if a jaw crusher meets production requirements, jaw crusher is used; If two jaw crushers are required, a gyratory crusher should be considered.

Gyratory Crusher Application

Gyratory crusher is a typical coarse crushing equipment in large scale dressing plant. Gyratory crusher and jaw crusher can be used as coarse crushing machinery, compared with the two, the advantages of gyratory crusher are: The crushing process is carried out continuously along the circular crushing chamber, so the production capacity is large, the unit power consumption is low, the work is more stable, suitable for crushing flake materials, the particle size of broken products is more uniform.

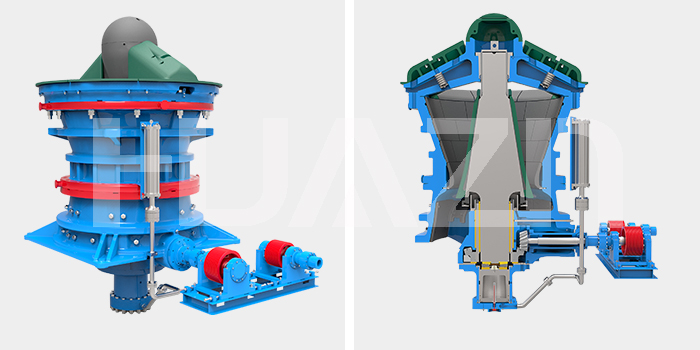

Luoyang Dahua Gyratory Crusher

Max. Feed Size: 1065-1525 (mm)

Processing Capacity: 2000-8880 t /h

- The special deep-cavity crushing chamber and longer feed opening designed, which make the feeding smoothly and realize the continuous crushing. GC series gyratory crusher has large throughput, high-efficiency crushing, big crushing ratio, superior product shape and easy maintenance, as well as less liner wear and low operation cost.

- The main shaft can be easily adjusted by its positioning control system to make up for the liners wear so that controlling the product shape.

- The balance cylinder system can prevent main shaft runout. This system can make the main shaft falling automatically under overloading, which avoid the main shaft runout impacting on the equipment when the large block of materials entered into the machine, to ensure the safe and stable running.

- GC gyratory crusher equipped with pressure dust control system can effectively prevent dust from entering into the eccentricity device and transmission device of equipment, which can extend the service life of the bearings.

- The high-strength extra-heavy frame, integral large main shaft assembly and high-performance bearings, which can ensure the service life of machine is more longer, the operation is more safe and reliable under kinds of bad working conditions.