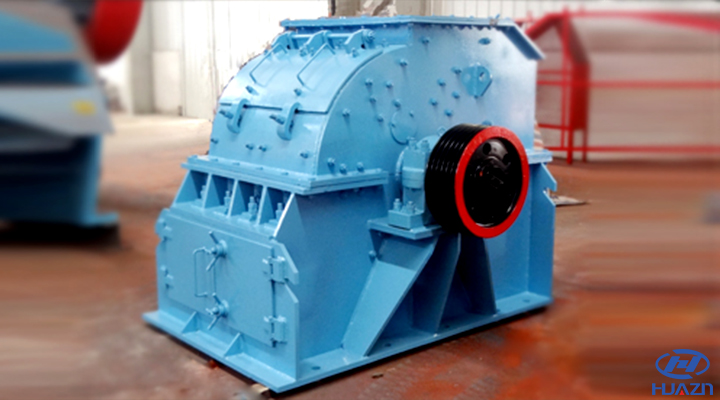

Hammer crusher, referred to as hammer mill crusher, is a kind of equipment for crushing materials in the form of impact, which can directly break materials with particle size of 600-1800mm into 25 or below 25mm. Hammer crusher is suitable for fine crushing of medium hardness materials in cement, chemical, electric power, metallurgy and other industrial sectors, such as limestone, slag, coke, coal and other materials.

Applicable materials: granite, basalt, limestone, pebble, cement clinker, quartz stone, iron ore, bauxite, construction waste, salt, brick, and coal, etc

Applied fields: mining, smelting, building materials, roads, railways, water conservancy and chemical industries.

Product structure: Hammer crusher is mainly composed of crusher body, rotor, hammer head, impact lining plate, sieve plate and so on.

Hammer crusher features

- Simple and compact structure

The overall design is beautiful, the hammer body is sealed, which solves the problem of dust pollution and dust leakage in the crushing workshop.

- One feeding molding, large crushing ratio, high production efficiency

Simplified process, one feeding, no need for multiple crushing, high output, reliable performance, and large processing capacity.

- Wear resistance, impact resistance, energy saving and environmental protection

The hammer head adopts new casting technology, wear resistance, less wearing parts, and easy maintenance.