In order to meet the requirements of different users on the granularity of crushed materials, stone crusher manufacturers have produced the impact crusher that can adjust the granularity of discharge size flexibly. So in the actual operation process, how to adjust the discharge particle size of impact crusher? The specific methods are as follows:

- Adjust the rotor speed: the rotor speed is determined by the linear speed required by the plate hammer. The linear velocity of the hammer is related to material properties, particle size, crushing ratio, machine structure, wear of the hammer and many other factors. The rotor linear velocity is usually 15~40m/s for coarse crushing and 40~70m/s for fine crushing.

- Adjust the impact frame: the gap and position of the impact frame can also adjust the discharge particle size.

1) By adjusting the clearance of the front and back impact frame or replacing the seriously worn lining plate and plate hammer;

2) In addition, it is to adjust the position of the impact frame, so that both sides of the frame and the lining can achieve a relative gap to ensure the discharge particle size.

- Adjust the gap between the impact plate and the crushing chamber: adjusting the gap between the impact plate and the crushing chamber can adjust the discharge particle size, and the gap adjustment of the equipment can be adjusted by mechanical or hydraulic system. The hydraulic control system can easily adjust the clearance through the local operation button or the transport control system.

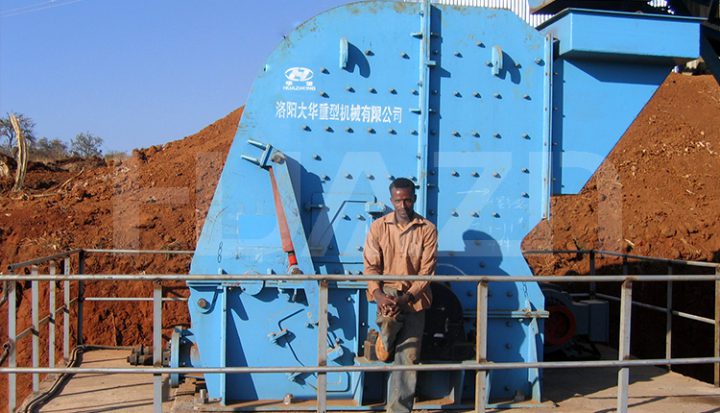

Luoyang Dahua has 60 years of development history, specializing in the production of crushing and grinding equipment. The products are obtained ISO9000 certification, quality is more reliable. The company also has rich experience in equipment selection and production line design and construction. We provide production line design service for 200,000 + customers worldwide. If you want to know more about the crusher machine, please contact us at any time.