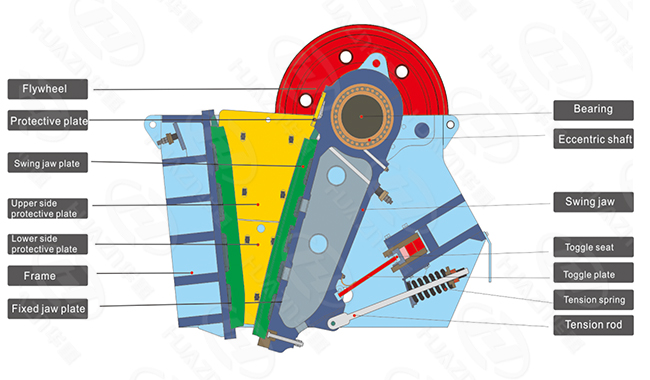

The jaw crusher is a widely used coarse crushing machine, capable of breaking materials below 1500mm, making it an indispensable equipment in the sand and stone industry. However, during usage, there are often issues encountered, and one common confusion among users is how to adjust the size of the finished product. This article aims to provide a detailed explanation on this matter.

The commonly employed techniques for adjusting the discharge size of jaw crusher are as follows:

1, Gasket adjustment

The top bolt is utilized to access the adjusting seat, where inspection of the rear thrust plate support and the rear wall of the frame takes place. A set of spacers with equal thickness are added or removed accordingly, in order to increase or decrease the discharge opening size of the crusher. The adjustment device of this kind features a simple structure, compact design, and minimal increase in overall weight, making it widely utilized.

2, Hydraulic adjustment

The rear thrust plate serves as the safety assembly of the crusher, and a hydraulic safety device is equipped in most jaw crushers to automatically adjust the size of the discharge opening. This ensures reliable and secure operation while facilitating fault clearance.

3, The utilization of inclined iron auxiliary adjustment

The transmission device enables the rear inclined iron to lift and the front inclined iron to move horizontally. The size of the discharge port can be adjusted accordingly when the rear inclined iron is raised or lowered. The adjustment device enables seamless adjustment without the need for interruption during the process.

4, Electric control mechanism

The electronic control mechanism enables efficient and precise adjustment and detection of the crusher, ensuring highly accurate control over particle size levels. This eliminates the need for repetitive operations and provides a significant level of differentiation and precision.

5, Support device adjustment

The bearing part of the jaw crusher utilizes a plain bearing cast with babbitt alloy, which exhibits excellent resistance to wear and can withstand significant impact loads. However, it operates at a relatively low efficiency and necessitates forced lubrication.

The above five types of adjustment methods for jaw crusher are more commonly used to adjust the discharge opening size, which can improve the maneuverability of the jaw crusher and effectively reduce the resource consumption of the screening operation. The machine, however, can be categorized into small and large sizes with different adjustment methods. Generally, hydraulic adjustment is adopted for large machines while gasket or support device adjustment is preferred for small machines.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.