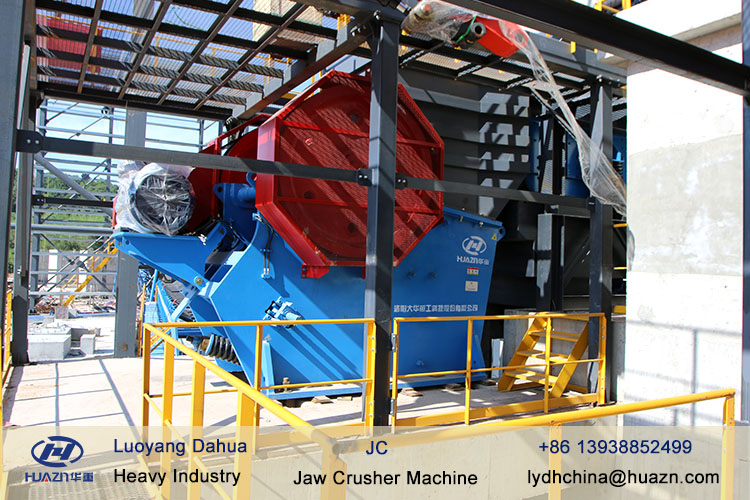

The choice of crusher type is crucial for cement manufacturers when constructing a cement production line. Opting for the appropriate crusher model can maximize the potential of the production line, resulting in products with a particle shape that meets industry standards and generating profits for customers. The selection of crushers is crucial as there are numerous types available, each with varying performance. Customers should consider factors such as material characteristics, production requirements, and the production environment when choosing a crusher. Luoyang Dahua Heavy Industry is here to provide you with a simple analysis.

Firstly, the hammer crusher and impact crusher operate on the principle of impact, resulting in a higher crushing ratio. As a result, typically only one stage of crushing is sufficient to meet the raw material crushing requirements for cement production. This is why they are referred to as single-stage crushers. By utilizing these two types of crushing equipment, investment costs can be significantly reduced. Of course, if the raw material has high moisture content or is viscous, it would be advisable to consider using a jaw crusher or gyratory crusher as a coarse crushing option, and then opt for a cone crusher for secondary crushing. In summary, customers should strive to make their selection as comprehensive as possible.

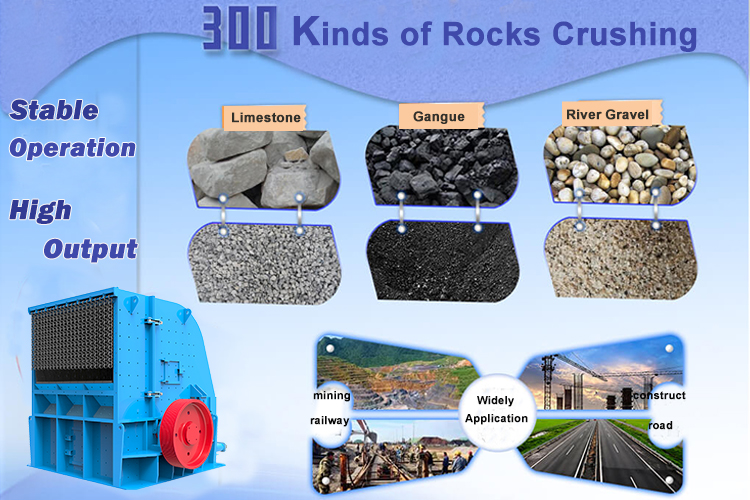

Luoyang Dahua impact crusher advantages:

1. Stable performance — continuous production and stable output

2. Vortex cavity – high yield, good grain shape

3. Big rotational inertia – reduce power consumption

4. High utilization rate of hammer head — the utilization rate of one through head exchange can reach 58.6%

5. High common rate of wearing parts — less stock and capital investment

6. Hydraulic start & adjustment — convenient adjustment and quick maintenance

7. New hammerhead clamping device – faster disassembly

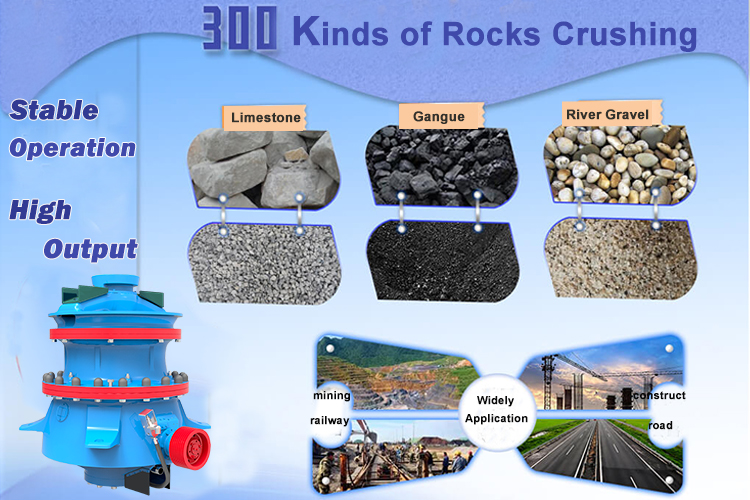

Luoyang Dahua cone crusher advantages:

1. The main shaft is a “simply supported beam” structure. Both ends support, the spindle bearing capacity is stronger.

2. Large feeding opening, elongated crushing chamber, and the top frame is divided into upper and lower parts. Dynamic pressure lubrication system of eccentric sleeve can reduce the temperature of bearing after heating.

3. Automatic system with overload protection and iron protection function. It can monitor oil temperature, oil quantity, crushing pressure, and size of feed opening, etc.

4. Adoption of lamination crushing principle makes the machine has high production efficiency, large processing capacity, better particle shape and lower unit energy consumption.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.