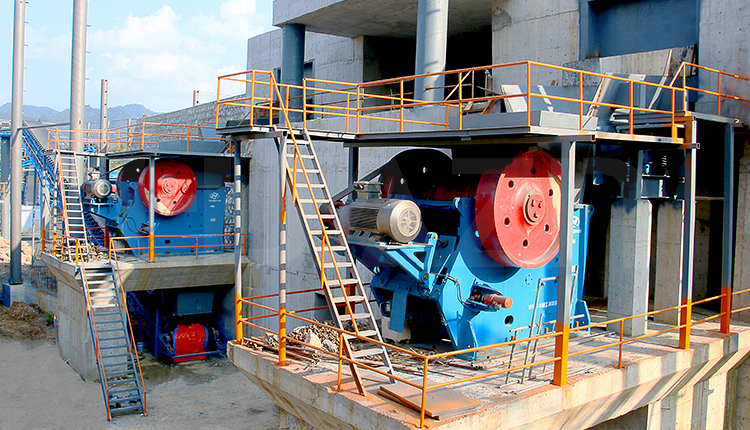

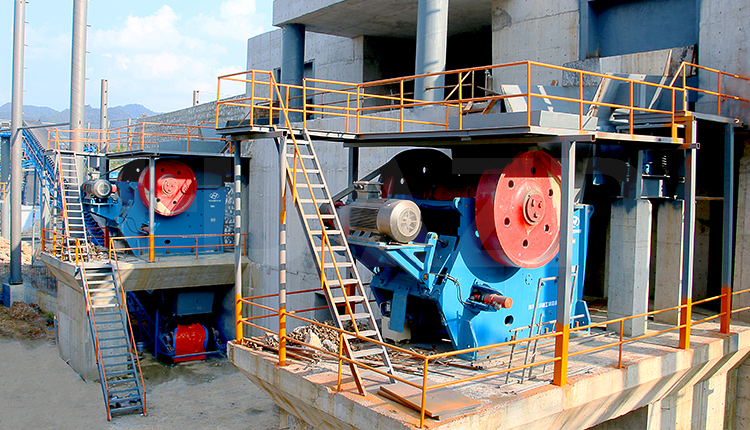

Limestone has great utilization value in metallurgy, mineral processing and other industries, and is also the main raw material for cement production. After crushing, limestone can be processed to reach the required granularity, the use of limestone crusher is very important. In the process of operating limestone crusher, it needs to standardize operations, ensure personnel and equipment safety to guarantee the normal production.

Check before starting the crusher

1. Check whether there are materials in the feeding machine, or in the crushing cavity. Clean them if have.

2. Check whether the crusher bearings, hydraulic equipment and dust collector is lack of oil.

3. Check whether the electric meter is in zero position, whether all signals and accident switches are in good condition.

4. Check whether there is foreign body on the belt, or the belt is drifting, or the condition of belt connector.

5. Check the articulated device in closed side, and lock it by using the interlock device.

6. Disconnect rotor rotation device, install protective cover and use the interlock device to lock.

7. Adjusting impact plate, clearance between crushing plate according to production demands. Turn the switch in automatic operation position after adjustment.

8. Lubricate all the parts that related to the operation in downtime.

Start the crusher machine

Observe the indicator according to the operation manual in start and stop process. Before starting or making the crusher machine running, should ensure no one is in danger.

Stop the crusher machine

1. Stop crusher after the materials in the crushing cavity are completely discharged.

2. Stop crusher belt, dust collector, and the conveyor belt of stacker after all the materials are transported.

3. Check and maintain crusher machine according to Equipment Standard and make record.

Inspection Items

1. Inspect and adjust the right position of the instruments. When the belt runs properly, adjust the material feeding speed accordingly. When adjusting the feeding speed, please gradually increase the feeding amount to meet the material feeding requirement.

2. Pay attention to the material falling to avoid relieving tooth and iron falling into the crusher, which may lead to the broken of jaw crusher and lower belt.

3. Control the mud content of the raw material. Material size over 1500mm x 1100mm x 1100mm is not allowed to send in jaw crusher.

4. Regularly check the temperature of the bearing during machine operation. (The maximum allowed temperature is 1000℃) and listen whether there is abnormal noise during operation.

5. Regularly check the temperature of the motor, the current should be within control according to the rules.

6. Regularly check the connector of the hydraulic pipe and each driving units to see if there exists loosing or leakage phenomenon.

7. Stop the jaw crusher immediately when hearing severe shaking and friction etc abnormal noise. If the main bearing of the jaw crusher has severe oil leakage, please stop the machine immediately.

8. According to the moisture content of the material, granularities size, adjusts the feeding quantities to prevent device blockage and over-load of motor and belt.

9. If emergency break down happened, stop the machine first and report the accident. Before the break down is solved,do not boot the jaw crusher by force.

10. When electronic devices break down, please find electronic engineer to solve the problem. Before the problem is solved, please do not boot the machine.

11. During machine operating, please do not touch, scrub any moving parts. Regularly check the belt working condition to prevent the flap of the valve, blockage or off tracking.

12. Stop the machine with load is not allowed. If the machine stops suddenly due to accident, please find out the reasons before starting the machine. If the machine still has large quantities of material, please reduce the loading before booting the machine. (Jaw crusher should be thoroughly cleaned before reboot).

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.