In recent years, there have been an increasing number of individuals expressing interest in investing in a stone crusher plant; however, only a few have achieved success. Before starting, we must take into account numerous factors, including the scale of investment, budget for investment, selection of crusher plant machinery, process design and other relevant considerations.

This text will explore what is the stone crusher plant and the stone crusher plant main equipment.

What is a stone crusher plant?

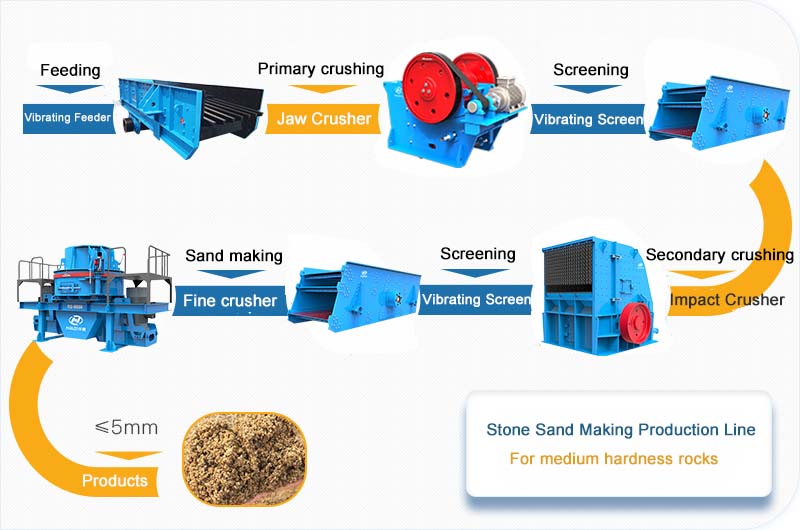

The stone crusher plant is generally divided into three stages: the coarse crushing of the jaw crusher, the medium and fine crushing of the impact crusher or the cone crusher and the sand shaping of the sand making machine. They all work together to crusher stone as efficiently as possible. Conveyor connects each machine, moving the crushed stone from one station to the next.

Step 1: Primary crushing

The large materials are fed into the jaw crusher using a vibrating feeder for the first crushing. Here, the large stone are broken into small piece for the secondary crushing step. Vibrating feeder can prevent oversized stone from getting into the crushing cavity and jamming or damaging it. Primary jaw crushers are really important in a stone crusher plant setup as they are able to handle large stones and can take a lot wear-and-tear.

Step 2: Secondary crushing

At this step, the stone materials need to be further broken that have come out of the primary jaw crusher. Conveyors then move the material to a secondary impact crusher or cone crusher, where it can be broken down further into smaller, similar-sized pieces. The output of an impact crusher is great for making graded aggregate.

Step 3: Sand making

The stones from the impact crusher or cone crusher are transported to the sand making machine. They are finely crushed and shaped below 5mm. If the customers require clean stone materials, the sand washing machine can be added.

The main crusher equipment in stone crusher plant

Gyratory crushers – can be used in place of jaw crushers for primary crushing and are ideal for harder materials.

Impact crusher – good secondary crusher for soft rock, like limestone.

Cone crushers – are a great alternative to impact crushers and are better for producing less flat and flaky products.

Sand making machine – for sand shaping and making by alternatively change the working principle of “stone beat stone” and “stone beat iron”.

Luoyang Dahua understands that setting up a stone crusher plant can be challenging, we are here to help you with everything you need. The company offers a full range of crusher equipment, grinding mill machine, and mobile crusher for each stage of your plant. Please contact our Online Service to get latest information.