The sand and stone production line is a specialized equipment used for the manufacturing of building sand and stone. It can break rocks, sand, pebbles, and other materials into various particle sizes that meet the requirements of building sand. The produced sands and stones have uniform particles and high compressive strength, making it highly suitable for construction purposes while also enhancing overall construction quality.

The sand making production line consists of a vibrating feeder, crusher, sand making machine, vibrating screen, conveyor belt, and other equipment. However, due to variations in material technology, the models of equipment used in the sand making production line may differ. In order to ensure efficient collaboration among multiple equipment and maintain the smooth operation of the sand and gravel production line, it is essential to install and operate the equipment correctly. Therefore, what precautions should be taken during the operation of the sand and gravel production line?

1, Before commencing the operation of the sand production line, a meticulous inspection should be conducted to ensure the impeccable condition and absence of any issues in all equipment components. This encompasses verifying the secure closure of sliding doors and ensuring the robustness and dependability of the equipment foundation.

2, The devices should be started in the designated startup order, which is typically conveyor, crusher, and vibrating screen. Prior to starting the subsequent device, ensure that the preceding device is operating smoothly. Following production, ensure thorough equipment cleaning to eliminate any residue.

3, The feeding process should strictly regulate the granularity and hardness of the stone to ensure its compliance with crusher requirements. The introduction of excessively large or unbreakable materials into the crusher may result in significant equipment wear or substandard sand quality.

4, In the production process, if abnormal ringing or abnormal operation of the equipment occurs, it is essential to promptly halt operations for inspection and resolution. In cases where foreign matter cannot be broken down within the equipment, feeding should be suspended to prevent blockages. During normal operation, it is crucial to maintain a consistent feeding speed.

5, The daily maintenance of sand making equipment is usually given great attention to in order to ensure the smooth progress of the sand production line.

What crusher equipment should be used in sand making production line?

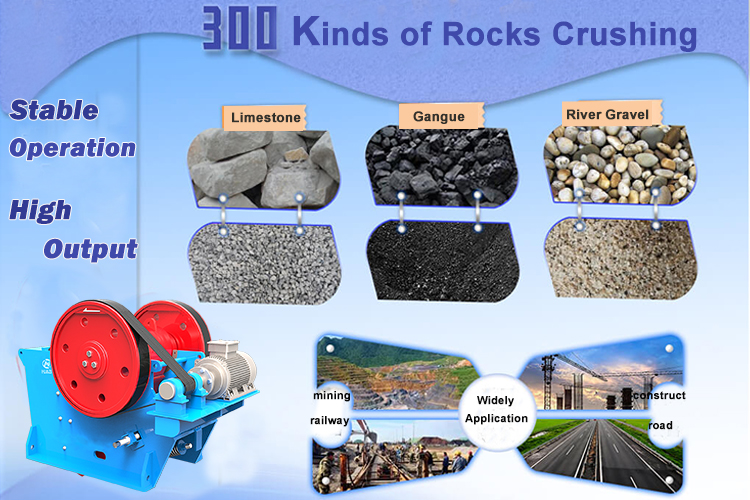

1, JC series jaw crusher

The JC jaw crusher is a commonly used primary crushing equipment, boasting the advantages of a large crushing ratio, high efficiency, simple structure, easy maintenance, and convenient operation. The feed opening can meet the feed ≤1300 mm, the production capacity is 50-2000 t/h.

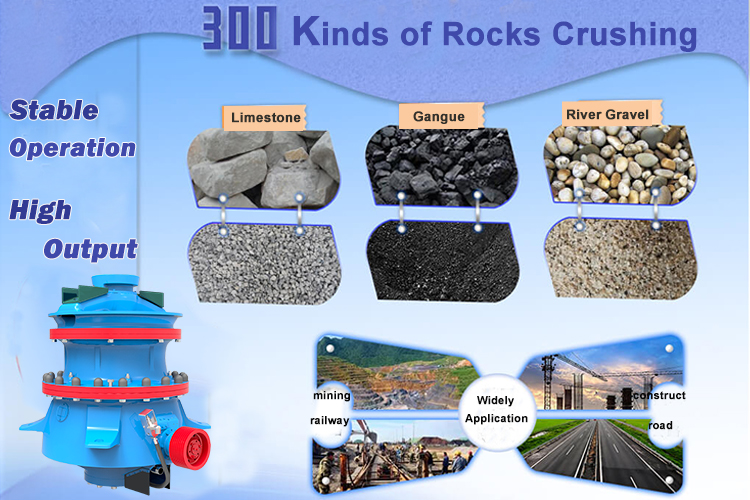

2, GPY cone crusher

The cone crusher adopts the principle of laminated crushing and is primarily used in the crushing process of high hardness stones. This cone crusher has strong wear resistance, advanced manufacturing processes, a high degree of intelligent control, a large output capacity, and good environmental protection. GPY single-cylinder hydraulic cone crusher can handle both coarse and fine crushing operations. The feed material is 35-670 mm, production capacity is 45-2188 t/h.

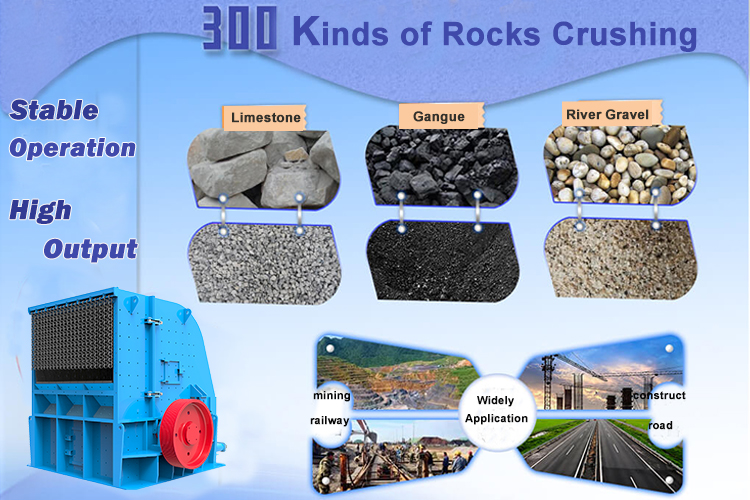

3, PFQ impact crusher

The PFQ series impact crusher is good at handling both soft and brittle materials with remarkable discharge particle shape, minimal needle content, and cost-effectiveness. It is widely employed as a crushing processing equipment, feed opening can meet the feed of 150-700 mm, production capacity is 50-1000 t/h.

4, PLS sand making machine

The PLS vertical shaft impact crusher (sand making machine) is used for stone sand making. The machine has the capability for sand making and stone shaping. The produced sand has uniform particle size, and fine grain shape. The feeding material is 5-60 mm, production capacity is 24-1100 t/h.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.