In the process of crushing iron ore, a feeding machine, primary crusher, secondary crusher, screening machine, fine crusher and dry magnetic separator are commonly used. Usually, the smaller the size of ore fed into the dry separator, the higher the proportion of iron ore that is obtained.

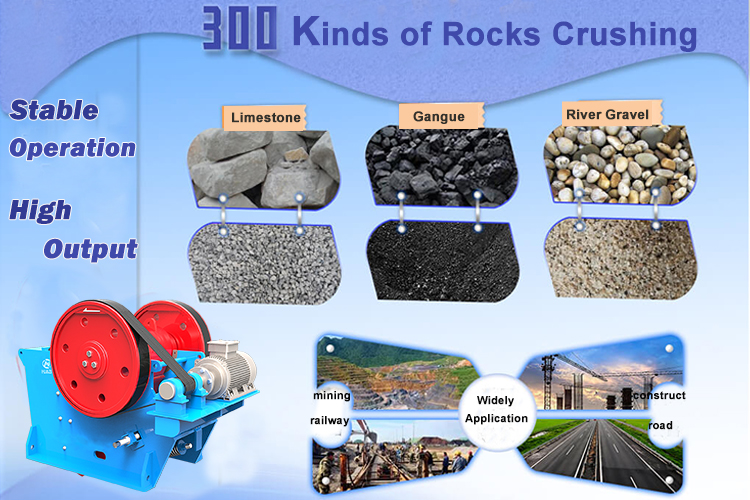

In the process of iron ore production, jaw crushers are commonly used, while large-scale production units (especially foreign mines) prefer gyratory crushers. Jaw crusher is a traditional, stable and reliable coarse crushing equipment, which has a wide range of applications.

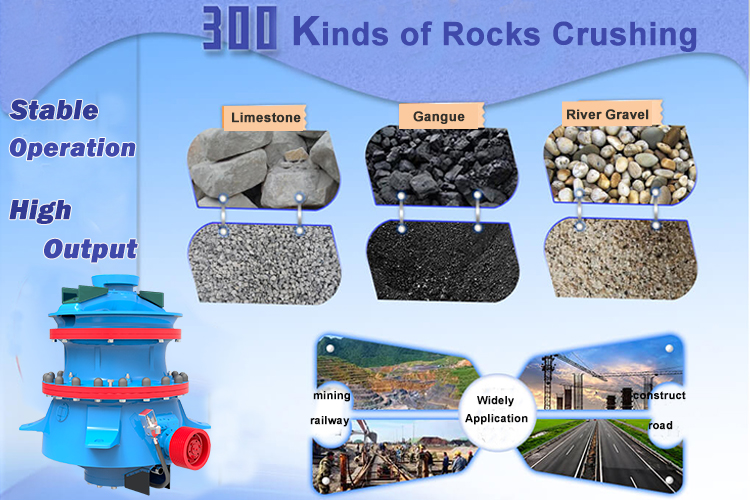

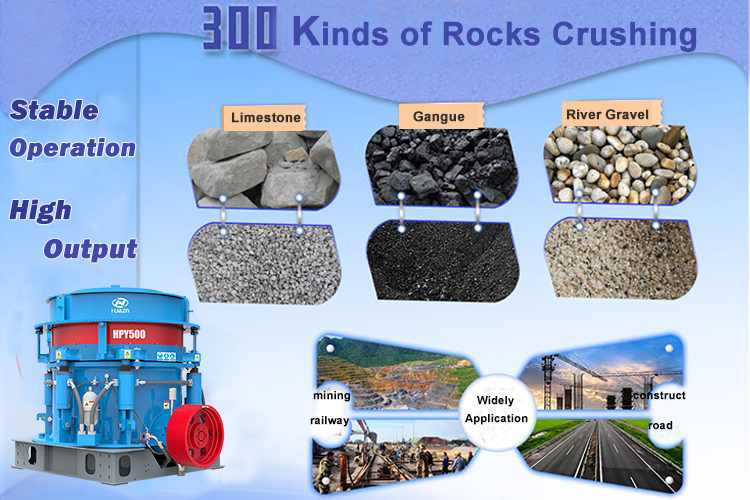

In the production process of iron ore crushing, the second stage crusher equipment is: fine jaw crusher and cone crusher.

The fine jaw crusher is typically utilized for smaller iron ore sites, having low equipment price, a simple structure, and convenient maintenance. However, the discharge opening of the fine jaw crusher can only be adjusted to a minimum of 25mm, resulting in a crushing particle size generally below 40mm.

Cone crusher structure is more intricate, rendering the equipment of higher price. Nevertheless, it yields greater output and finer crushing particle size while also extending the service life of wear-resistant components. Therefore, the cone crusher is extensively utilized in relatively large iron ore mines.

From the perspective of production efficiency and cost reduction in iron ore mining, the utilization of cone crushers can effectively lower operational expenses. Because cone crushers can produce smaller product particle sizes, the use of laminating equipment to complete the main crushing task of iron ore is a highly economical production method in terms of overall process efficiency.

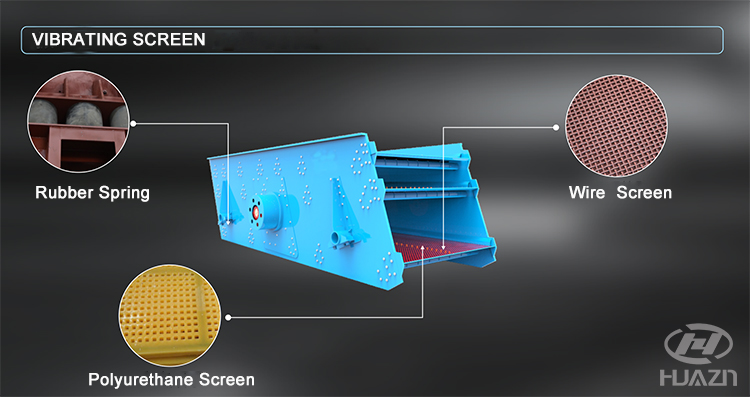

Circular vibrating screens are commonly used in screening equipment to screen materials after the second stage of crushing. Generally, vibrating screen materials with a size of 10mm or smaller can be screened for dry selection. Materials ranging from 10-40mm are fed to the fine crusher for further crushing operations, while those exceeding 40mm in size are returned to undergo secondary crushing. Naturally, the screening size range can be adjusted according to the actual requirements to achieve cost-effectiveness.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.