Hydraulic cone crusher is widely used in the medium and fine crushing of various minerals and rocks in metallurgy, mining, sand aggregate, cement mining and other industries. It can crush hard rocks such as river pebbles, granite, basalt and dolomite. Hydraulic cone crusher can be divided into single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher. For many users, they do not know the difference between the two, and often do not know where to start when choosing. Let’s analyze the difference between single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher. It is convenient for you to choose the equipment that is more suitable for your needs.

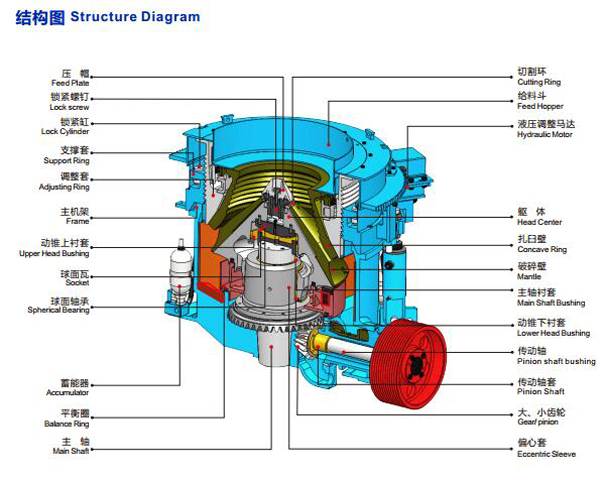

1. Structure composition

The structure of the single-cylinder hydraulic cone crusher is divided into six parts, which are the upper frame assembly, the lower frame assembly, the moving cone assembly, the drive shaft assembly, the eccentric sleeve assembly, and the hydraulic cylinder assembly. The structural characteristics of the single-cylinder hydraulic cone crusher are simple structure, few parts, beautiful appearance, convenient maintenance and easy automatic control.

The structure of the multi-cylinder hydraulic cone crusher is also divided into six parts, which are the lower frame part, the eccentric sleeve part, the transmission part, the support sleeve part, the adjusting ring part, and the moving cone part. Multi-cylinder hydraulic cone crusher has good performance, but compared with single-cylinder, this type of crusher has more complicated structure and higher manufacturing hours than single-cylinder.

2. Finished product size

The single-cylinder hydraulic cone crusher adopts the unique shape of the crushing cavity and the principle of lamination crushing to produce the crushing effect between particles, so that the proportion of cubes in the finished product is obviously increased, and the needle-like stones are reduced. However, due to the restriction of structural conditions, the stroke of single-cylinder hydraulic cone crusher is much shorter than that of multi-cylinder hydraulic cone crusher. In terms of single-particle material crushing, the stroke of the single-cylinder hydraulic cone crusher cannot promote the material in the crushing cavity to achieve inter-particle crushing. The swing speed of the crushing cone of the multi-cylinder hydraulic cone crusher is much faster than that of the single-cylinder. Therefore, the percentage of fine particle content in the finished product of the multi-cylinder hydraulic cone crusher is higher and the product is more uniform.

3. Over-iron protection

When the single-cylinder hydraulic cone crusher passes iron and cleans the cavity, hydraulic oil is injected into the accumulator, and the main shaft falls. After the iron passes, the accumulator quickly presses the oil back. When it runs normally, hydraulic pressure is still used for cavity cleaning pump, multi-cylinder overload protection. When foreign matter passes through the crushing cavity or is overloaded, the hydraulic safety system can enlarge the discharge port and discharge the foreign matter from the crushing cavity. If the foreign matter is stuck in the discharge port, the cavity cleaning system can be used to improve expand the discharge port in one step to discharge foreign matter, and the discharge port can automatically resume normal work.

4. Lubrication system

When the single-cylinder cone crusher is filled with oil, it enters from the lower end of the main shaft all the way to lubricate the spherical bearings, spherical bushes, frame bushings, main shaft, bushings, and then lubricate bevel gears. It can also enter from the end of the drive shaft to lubricate the drive shaft bushing, and the two oils are discharged from the same oil outlet. The oil injection of the multi-cylinder cone crusher enters from the lower part of the machine, and after reaching the middle part of the main shaft, it is divided into three branches. The inner and outer surface of the eccentric sleeve, the oil hole in the middle of the main shaft reaches the ball bearing, and the bevel gears of small and small are lubricated through the hole.

5. Broken effect

The single-cylinder hydraulic cone crusher has high crushing efficiency, flexible discharge port can be directly adjusted, and the discharge particle size is relatively unstable. The multi-cylinder hydraulic cone crusher is laminated crushing. The faster the swing speeds, the better the laminated crushing effect. The swing speed of multi-cylinder hydraulic cone crusher is much faster than single-cylinder hydraulic cone crusher. The level of fine particles in the finished product is high and the product size is more uniform.

6. Scope of application

The single-cylinder hydraulic cone crusher has a better effect of crushing a single material, but if the material in the crushing cavity is to be crushed between particles, the single-cylinder hydraulic cone crusher is not as effective as the multi-cylinder hydraulic cone crusher. In terms of equipment application scope, multi-cylinder hydraulic cone crusher is quite extensive. Under the same power and production time, the output of a multi-cylinder hydraulic cone crusher is about twice that of a single cylinder.

Single-cylinder and multi-cylinder cone crushers have their own advantages. Which hydraulic cone crusher is better? Due to different crushing processes and different crushing particle shape requirements, the equipment selection standards are different, so which hydraulic cone crusher has better chances depends on the actual production situation of the user. Luoyang Dahua Heavy Industry has a variety of different models for single-cylinder cone crusher and multi-cylinder cone crusher according to the production demand. If you are not sure how to choose, you can also compare your actual production situation and the output, the requirement of particle size tells us that we will choose a suitable hydraulic cone crusher for you according to your actual requirements!