Whether the machine-made sand is good or not the sand making machine plays a vital role, but what kind of sand making machine has good sand? This question is not easy to answer, because each type of sand making machine is suitable for different situations, and the purpose of the sand produced is also different. The appropriate one is good. Therefore, we must not only understand the model and performance of the sand making machine, but also carefully understand the crushed materials. Recently, a customer inquired, "The sand making machine I bought feels that the output of the original customized sand cannot be achieved". Why? Don't worry if it is the problem of the sand making machine. Give you a comprehensive analysis and see if it is caused by the following problems.

1. Different crushed materials. The hardness, viscosity, humidity, etc. of different materials will have certain differences, and the amount of sand produced by the sand making machine during crushing will also vary depending on the material being crushed.

2. The fineness of finished sand is different. The higher the fineness requirement, that is, the finer the finished material is required, the smaller the sand making capacity. For example, the PLS series sand making machine of Luoyang Dahua Heavy Industry is divided into crushing sand making mode and high-speed fine crushing and shaping mode. Take the PLS1000 most frequently bought by customers as an example. When crushing and making sand, the maximum input is 60mm and the production capacity is 200~410t/h; for high-speed fine crushing and shaping, the maximum input is 5mm and the production capacity is 150~250t/h. This is related to the intensity and output demand of sand making users.

3. The difference of sand making machine models. The model of sand making machine produced by each manufacturer is different, and the sand output and energy consumption of different models of equipment during operation are different. When purchasing equipment, users should have a certain understanding of their own production and buy a suitable sand making machine; otherwise it will not only affect the output, but also may cost the user higher costs.

4. Whether to regulate operation and regular maintenance. Standardized operation and regular maintenance of the sand making machine are very important and will also affect the sand output of the equipment. The continuity and uniformity of feeding have a great influence on crushing. Continuous and uniform feeding can not only normalize production, but also increase productivity. If the sand making machine operates irregularly during operation and does not do regular maintenance, it will cause the wearing parts to accelerate, greatly reduce the life of the equipment, and reduce the output.

5. Quality of sand making machine. The high-quality sand making machine is not only energy-saving and environmentally friendly, but also can easily achieve the expected output. And high-quality manufacturers will choose new wear-resistant materials and adopt more advanced production technology, so that the equipment produced can meet the production needs of users.

6. Scheme design of sand production line. The final output is related to the equipment of the entire production line. For example, if the output requirement is 500t/h, the hourly output of the sand making machine cannot only reach 500t. The processing capacity of the front jaw crusher, cone crusher, belt conveyor, etc. must also be matched with it; otherwise the final output will definitely not meet the requirements. The configuration of a production line must comprehensively consider various factors to meet production needs.

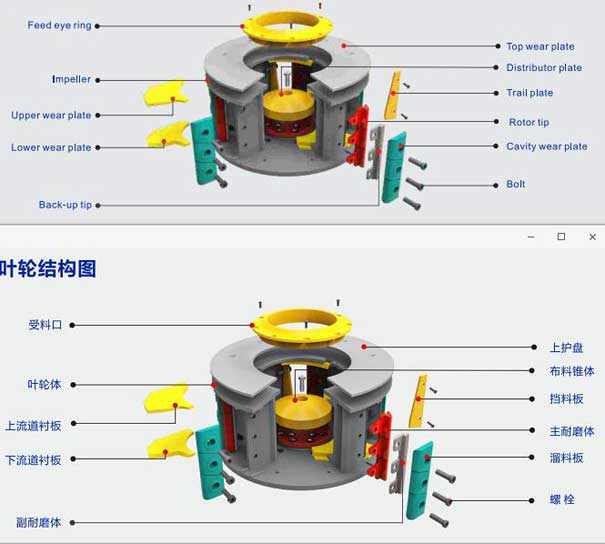

7. The influence of impeller speed. Continuous materials enter the high-speed rotating impeller, and after acceleration, a continuous flow of power is formed, which produces high-speed extrusion, grinding and crushing in the vortex cavity to obtain continuous crushing production. From the working principle of the vertical shaft impact crusher, when the particle size of the material has been determined, the kinetic energy will increase greatly as the linear velocity of the crusher rotor increases; when the linear velocity of the crusher rotor is constant, if the mass of the material increases, the kinetic energy It also increases, and vice versa.

8. The influence of working parameters and operating factors. The performance and structural factors of the sand making machine have a great influence on crushing. The type and specifications of the sand making machine, the economical and reasonable installed power, the range of speed adjustment, the size of the discharge port, and the structure of the crushing cavity all have a greater impact on the crushing efficiency.

The failure of the sand making machine to reach the original output has a lot to do with the above 8 factors. The user should comprehensively consider his own production situation when purchasing, so as to find the equipment suitable for their material crushing. Therefore, when choosing equipment, we must clearly state our needs, so that manufacturers can equip equipment and production line designs according to our needs.