In recent years, the shortage of sand and gravel aggregates has artificial sand come from behind, making up for the huge gap in sand and gravel. In addition to the promotion of the development of machine-made sand by local governments, the promotion and application of machine-made sand is showing a prairie fire. Machine-made sand can be crushed from a variety of stones, mainly granite, pebbles, limestone, waste rock, construction waste and other materials. The sand making machine is an indispensable equipment on the artificial sand making production line, which can not only meet the production needs of users, It can also provide the country with high-quality sand and gravel aggregates. It is relatively easy to obtain raw materials, so it is not difficult to open a machine-made sand factory. So how much money can we set up a machine-made sand factory? Which sand making equipment investment is lower?

What sand making equipment to choose?

Maximum feeding particle size: ≤640mm; Discharge opening gap: 20~200mm; Production capacity: 7~310t/h; Power: 15~110kw.

DHKS series jaw crusher is a series of advanced jaw crushers designed and developed by Luoyang Dahua Heavy Industry, which has introduced and absorbed foreign technology. It is an alternative to traditional jaw crushers. This jaw crusher is a small jaw crusher. It adopts an integral welded structure frame, is rigid and reliable, and its crushing efficiency is high, durable, and easy to install and maintain. It is favored by many customers and can be widely used in mines, building materials, and highways, railway, water conservancy, chemical industry and other industries of various minerals and rocks.

2. PFL Series Vertical Complex Crusher

Maximum feed size: ≤240; Discharge size: ≤3mm (70%~90%); Production capacity: 8~200t/h; Power: 45~355kw.

The complex sand making machine is a small-scale sand making equipment. If your investment budget is small and the crushing materials are relatively soft, you can choose a complex sand making machine. The PFL series vertical complex crusher is a new type of fine crushing and coarse grinding product developed by our company based on the integration of similar crusher technologies at home and abroad and combined with the company's years of practical experience. The product has both impact and grinding crushing mechanisms. This series of products can achieve more crushing and less grinding. It is an ideal fine crushing equipment for energy saving and consumption reduction. It is also suitable for the fine crushing of various solvent raw materials in the iron and steel metallurgical industry and the crushing of various medium-hard rock minerals in other fields such as construction, building materials, and chemical industries.

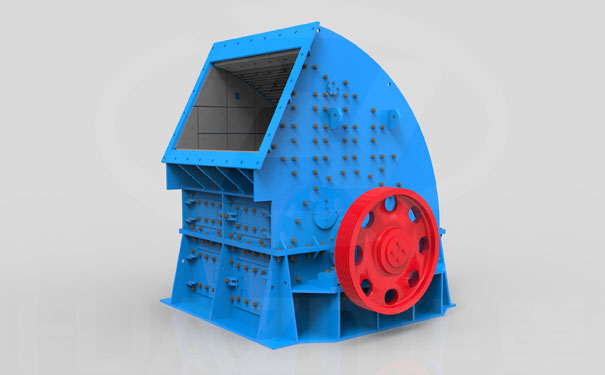

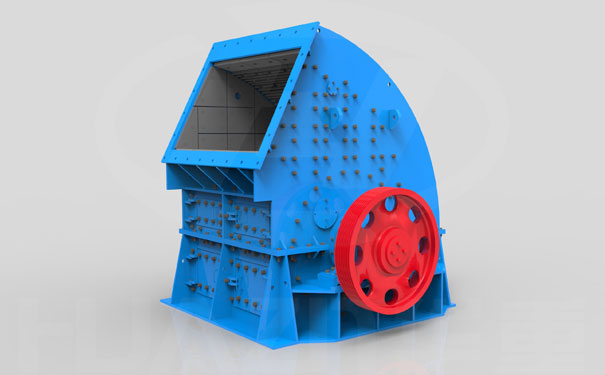

Maximum feed size: ≤1500mm; Production capacity: 250~2000t/h; Power: 160*2~630*2kw.

The obvious advantage of the hammer crusher is that the material is formed at one time, without other equipment, from stone to sand in one step, so it has less investment and low price. PCZ series hammer crushers are mainly used for stone crushing in the building materials industry, highway and railway construction, and other industries using stone materials. This product is suitable for the crushing operation of various materials of medium hard and below. It has the characteristics of unique structure, simple operation mode, high efficiency and energy saving, good product particle size, adjustable discharge particle size, and cost saving.

The above are the recommended small and medium-sized sand making equipment. Choosing this sand making equipment will have lower investment costs. Selecting the right equipment and optimizing the production plan. These factors are based on the selection of the equipment manufacturer. If the manufacturer is selected, a lot of equipment investment will be saved.