Vertical impact crushers (sand making machines) generally have two feeding methods: waterfall and center feeding and full center feeding. Which of the two feeding methods is better? What effect does it have on the quality of the discharged machine-made sand? Today, take Dahua Heavy Industry's PLS series vertical impact crusher as an example to understand the difference between the two feeding methods and the discharge of the vertical sand making machine.

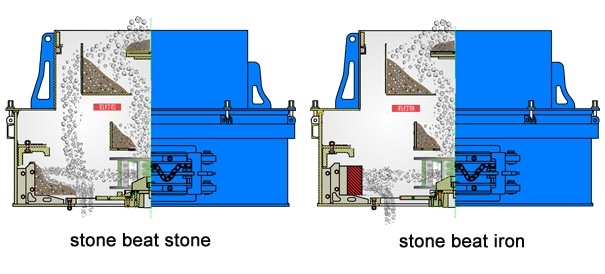

The PLS series vertical impact crusher has two crushing mechanisms, namely "stone beat stone" and "stone beat iron" by controlling the feeding method according to the working conditions or the different materials to be crushed.

"Stone beat stone" adopts the method of waterfall and center feeding. In the future, the material is divided into two paths according to a certain controllable amount. One way is introduced from the central feeding pipe into the horizontal high-speed rotating impeller cavity, and the other way is fed from the material. Multiple overflow ports on the circumference of the bucket fall into the inner cavity of the equipment, and the materials entering the inner cavity of the impeller are thrown out from three or more launch ports through the high-speed rotation of the impeller, and the materials falling from the overflow ports are strongly affected in the circumferential area of the impeller, the impact of the self-impact and the formation of rocks hitting rocks.

"Stone beat iron" adopts a full-center feeding method. The material will be introduced into the high-speed rotating impeller cavity from the central feed pipe, and then thrown out from three or more launch ports after being accelerated by the high-speed rotation of the impeller. The metal counter-attack plate on the inner wall of the crushing cavity forms the crushing of stone and iron. First of all, we should know what its working principles are?

After understanding the principles of the two feeding methods, what impact do these two feeding methods have on the discharge?

Waterfall and central feed: Mainly used for sand making, with large production capacity, and the output particle type is relatively inferior to the full central feed.

Full center feed: mainly used for shaping, the production capacity is relatively small compared to waterfall and center feed, but the finished product is better.

The "stone-beat-stone" crushing method is suitable for abrasive materials with medium hardness and above, such as basalt. During the crushing process, the material ejected from the spin plate impacts the material lining without direct contact with the metal elements of the equipment, reducing iron consumption and thus reducing maintenance time. The "stone-beat-iron" crushing method is suitable for materials with low abrasiveness below medium-hardness, such as limestone. The crushing efficiency is higher under the working condition of "stone beat iron".

After mastering the characteristics of the two feeding methods and discharging finished products, we can choose the appropriate feeding method according to our needs. We do not necessarily say which feeding method is better. If your demand is that the output is large, and the output is if the grain size requirement of the finished product is not high, choose waterfall and center feeding; if you require a good grain size of the finished product, you can choose full center feeding.