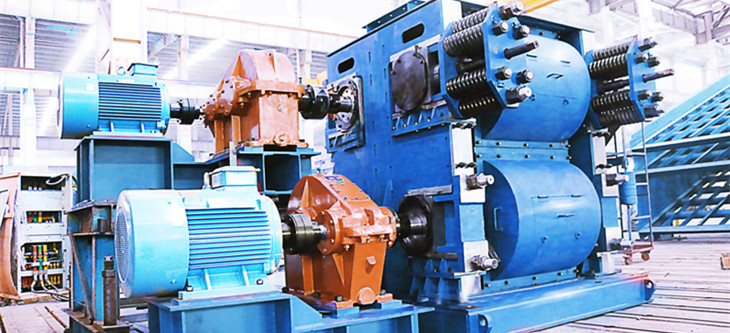

Roller crusher is a kind of crushing machine that is widely used in many industries. In order to guarantee the greatest crushing ratio, the right use and proper maintain should be carried.

1. Operator should carefully check the whole machine before start up, including checking bolt screwing, oil level of reducer and bearing lubrication.

2. Feed materials until the machine reach the normal running speed after the no load running without abnormal conditions. Stop feed, discharge all the materials out of the crushing chamber, and then stop the machine.

3. Complete inspection should be taken after long time idle or before primary start. Check the bolt is loose or not, the oil level is in the required limit or not, lubrication oil is sufficient or not, bearing add oil or not, the cable connection between circuit and control switch, materials inside crushing chamber. After check all the above factors, jog start the crusher, until the running direction is right, start the machine.

4. If found abnormal sound, temperature of drive system and oil system rise or strange smell, stop the crusher. Restart the machine after troubleshooting.

5. Motor bearing and main bearing of crusher machine should be cleaned once a year, and the reducer be cleaned and change oil also once a year.

6. Tighten the fastening of crusher machine every three month, and take regular inspection and maintenance.