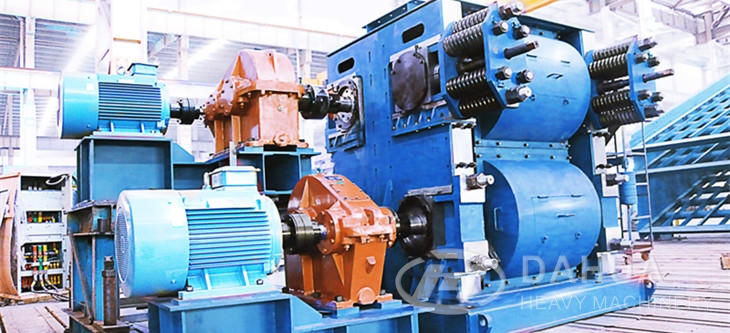

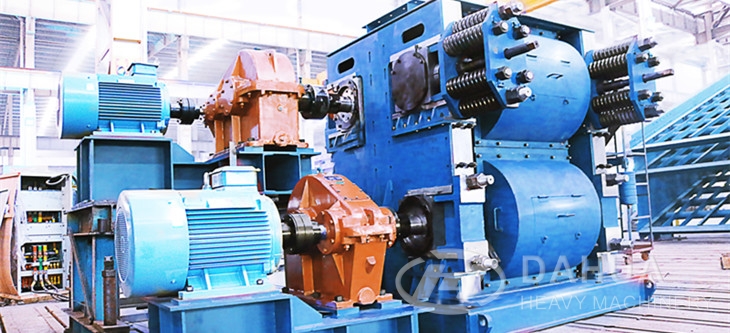

1. This kind of crusher achieves continuously crushing through double rotor, which can crush various kinds of wet materials and control the material size by adjusting the clearance between hammer head.

2. High alloy wear resistant hammer head. It has the combination form of hammer head and hammer handle, and only change the head if necessary.

3. Special position shift and clearance adjustment technology. When the hammer head is worn out, it's no need to repair, just shift the position for repeated use.

4. The crusher makes bi-direction rotation, which reduce the frequency for changing wearing parts.

5. Even discharge granularity, large crushing ratio, high output and low energy consumption

6. It is suitable for fine crushing brittleness material with less dust, low noise and not blocked.

7. Shorten the residence time of materials in the chamber, and prolong the service life of wearing parts.

8. Quick inspection. The side door on the top of the crusher can be opened that makes the inspection and change of the wearing part more convenient and faster, shorten the inspection time.

9. Electric-hydraulic operation. One person can operate, maintain and replace the machine parts.