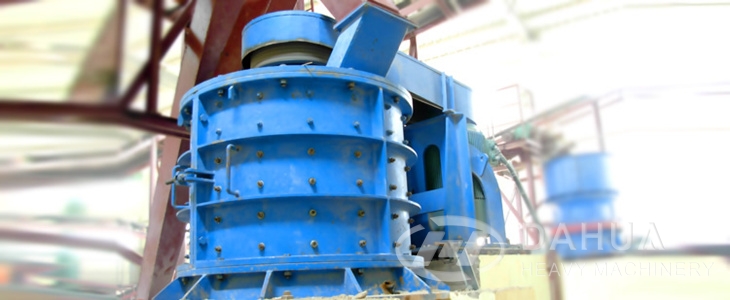

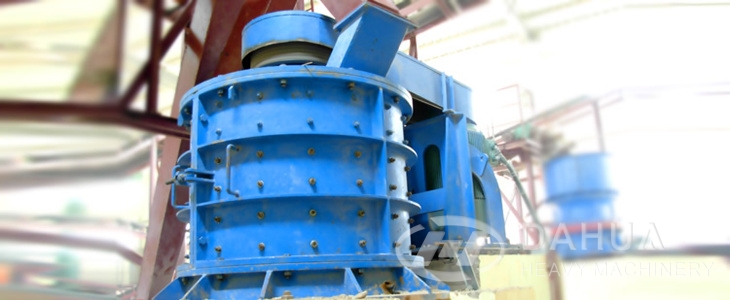

Medium and Fine cone crusher is also called cylinder milling machine. The working principle is the same as the coarse cone crusher, but there exists big difference in structure between these machines. The main differences are demonstrated below:

Coarse cone crusher features with steep dig angle. The moving cone is right in the middle, while the fixed cone is set upside down. For medium and fine cone crusher the dig angle is quite smooth and dig angle is quite small, moreover, two of its cones are right in the middle.

The moving cone of the coarse cone crusher is hanging on the beam through the main shaft. While, for medium and fine cone crusher’s moving cone, it is fixed on the spherical bearing.

Adjustment of the discharge opening is to adjust the moving cone. Whereas the adjustment of medium and fine cone crusher discharge opening is to adjust the fixed cone. (Except for the medium and fine cone crusher in single cylinder).

Medium and fine cone crusher can be classified into two groups. One is spring cone crusher, another one is hydraulic cone crusher. Among them, the hydraulic cone crusher has sing-cylinder and double cylinders two modes to choose. Besides above two kinds of cone crusher, each of them has standard, medium-size and short types for option. Three kinds of crushers share the same working principles and with the same basic structure, the only difference lies in the shape of the crushing chamber.