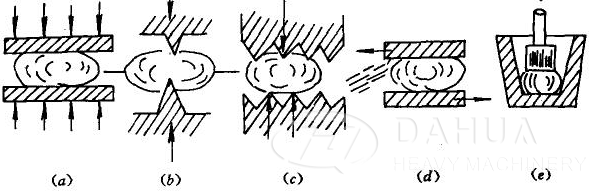

When Ore stone need to be crushed, in order to overcome the cohesive force, we must apply force. At present, for ore stone crushing, mechanical force is mainly applied as shown in the figure.

1. Stress crushing

As shown in the figure (a),it applies the stress force caused by two working face getting close to ore stone, this kind of force will increase gradually, and have a large range.

2. Splitting

As shown in the figure (b), it applied the splitting force to make stone crushed, this kind of force has a concentration of stress, usually leads to partly rupture

3. Fracture

As shown in the figure (c), when the stone being crushed, receiving a concentration of bending, which makes the stone break off and crushed.

4. Grinding

As shown in the figure (d), the working face make relative movement on the surface of stone, which make a cutting force to the stone, it mainly used for fine material.

5. Impact

As shown in the figure (e) ,it mainly applies the instantaneous impact force onto the stone, because of the high speed of impact, a big local stress come into being before the deformation extend to all of the stone, the impact force destroy the stone most effectively which is also called dynamic crushing

Impact crushing is most effective among above five crushing mode, grinding crushing is applied on the surface of ore stone, the crushing effect is poor, only apply to the fine granularity stone.

Stress crushing has a bigger contact area, so leads to large energy consumption, in splitting crushing ,ore stone receive a concentration of stress, the energy consumption is less, only 10%一20% compared to Stress crushing,

For the crushing equipment on the market nowadays usually applies the combination of above crushing mode.