Before the iron ore going through metallurgy process, in order to meet the requirement of the blast furnace process, the screening process is of great essential besides the crushing process. Screening process is to sort the material mixture with different granularities into different grades through single or multi layer screen. Sorting out large block and powder is the main objective of the screening process. Through classifying iron ores that are within the required range can not only improve the efficiency of the crusher, but also improve the composition of the materials so as to meet the high demand of the blast furnace process.

Below are the most common screening equipments that are used in the preparation of ore processing procedures.

(1) Cylinder Screen

Cylinder screen is widely used in the medium and fine screening process, especially for ores with heavy sediment content during washing. It is much more convenient to screen while washing. The screen has simple structure that is easy for manufacturing and management. When it works it has little vibration and barely has noise. The drawback of the screen is low screening efficiency. It also has grinding effect on the material during screening process.

(2) Fixed Screen

It is widely used for the large block material’s coarse and medium screening process. But such machine is of low screening efficiency ( Maximum efficiency is 50%-60%), large sliding angle ( not smaller than 40°-50°) and taking up large vertical space.

(3) Vibrating Screen

The vibrating screen is one of most widely used screening equipment in the industry. Vibrating screen with high efficiency screening, large capacity, no-blocking mesh hole, convenient adjustment, widely range of the particle size that suitable for the screening, also can be used for screening of medium and fine material. The disadvantage is that specialized transmission required and consumption power.

(4) Probability Screen

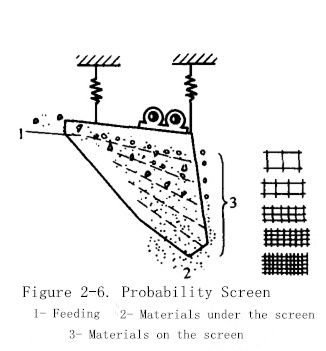

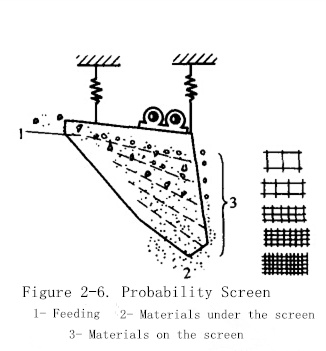

The probability screen is a kind of multilayer and new-type screening machine, which is the use of particles through the probabilistic difference of mesh hole to complete the screening. The structure principle is shown in figure 2-6.

Probability screen is characteristic of multilayer screen surface, large mesh and big slope angle. The significance lies in: multilayer screen surface can reduce the thickness of material layer of each screen surface; increasing the mesh size, which can make the fine grained material quickly through the screen mesh to reduce the blocking; the larger screen surface angle make the material movement accelerated greatly to improve the productivity and screening efficiency of machine. In addition, the probability screen has advantages with small volume, smart quality, low power consumption, easy to dusty, low noise, easy maintenance, etc. which is widely used for screening of coke and sinter under the ore tank.