The merit of hammer crusher: High production capacity, large crushing ratio, simple structure, low power consumption, easy maintenance and convenient for spare parts replacement, even products size and less over crushing.

The demerit of hammer crusher: Quick abrasion between hammer and disk, large water content or the grizzly bar is easy to be blocked when the materials content viscidity materials so as to reduce the production capacity and even lead to accident.

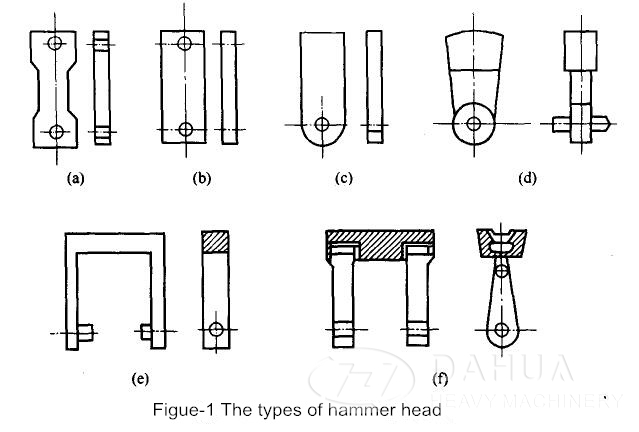

Hammer is the main parts of hammer crusher, its size, type, and weight is decided by the size of materials or the mechanical properties. The type is shown as figue-1.

The hammers in Figue-1 (a)、(b)、(c) suitable for crushing the medium hardness materials and the soft materials with granularity 100-200mm, the weight of hammer is from 3.5-15kg.

The hammers in Figue-1 (a)、(b) are the hammer that with two holes at both side, which can be used for four times by exchange after abrasion.

The hammer in Figue-1 (d) is the heavy hammer, its center of gravity is far from center, so it can be used to crusher big block (above 300mm) of medium hardness materials, and hammer weights 30-60kg.

The hammers in Figue-1 (e)、(f) are used to crusher hardness materials with the weight of 50-120kg. Because of the wear from materials, the end of hammer is easy to be worn, normally use manganese steel.