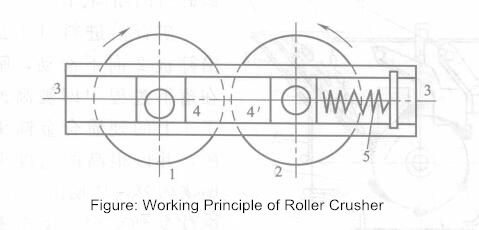

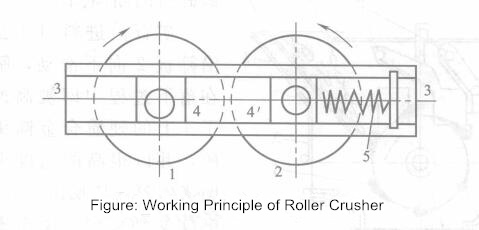

The following figure is the structure of roller crusher and its working principle.

The roller 1 is installed on the fixed bearing 4 on the frame 3, the roller 2 is supported by the movable bearing 4. These two rollers are driven by the separate motor and do the opposite rotation. The ores are fed from the top of the machine, and are crushed in the clearance that formed between the two rollers. Metal mine mainly uses the smooth roller surface, so the main breaking way is crushing, with some grinding function (if the roller is toothed surface, the main way is splitting crushing). The crushed materials are discharged under their own gravity. Because of the materials are only crushed one time through the two roller, the over crushing phenomenon is less.

Roller crusher has the feature of simple structure, reliable working condition, low price, easy maintenance, the crushed products have even granularity, less over crushing, and fine particle size (below 3mm). In this way, the machine is used in the small ore dressing plant (like tungsten ore) for the secondary and fine crushing of brittle materials and viscidity materials with soil. But the roller crusher's production capacity is low.