1. Semi-wet selective crushing and separation principle

Semi-wet selective crushing and separation carry out according to different kinds of strength and brittleness of municipal wastes, which are crushed into different granularity of fragments under certain humidity, then separated through different mesh. Because the process is in the condition of semi wet (plus a small amount of water), municipal wastes are crushed and separated selectively in the two functions of device, therefore, the device is called semi-wet selective crushing separator. Semi-wet selective crushing and separation can realize fully recovery of valuable material in the wastes.

2. Semi-wet selective crusher

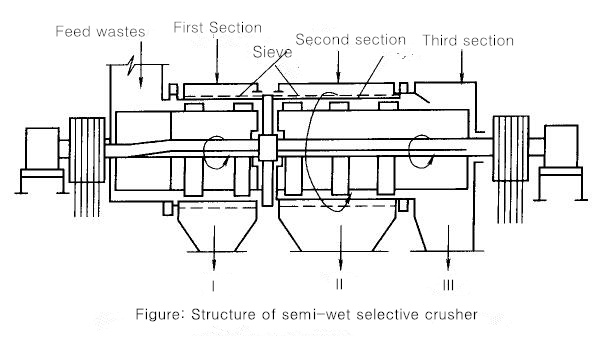

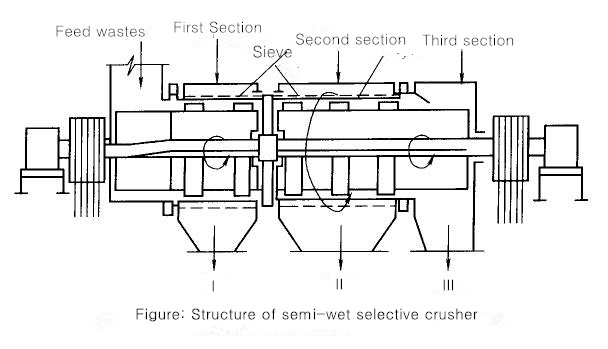

(1) Structure of semi-wet selective crusher

Semi-wet selective crusher is the crushing and screening machine which constitutes a simultaneously selecting and crushing process. It is composed of two kinds of rollers with different perforation sieve, in the rollers there are two speed scrapers corresponding with first and second screen. Separation device is divided into three sections, the first and second sections with screen, the third one without screen.

(2) Working principle

The wastes are fed into the head of cylinder screen, rise along the screen wall, and then fall on the contrarotation impact plate under self gravity. The brittleness materials like glass, pottery, tile, and kitchen waste, etc in the waste are crushed into flake, and are discharged from the mesh in the first section screen wall. The sorting machine separate the kitchen waste and glass, the other wastes are transport into the second crushing section. In this section, spray water on the wastes, the medium granularity like paper change into pulp and discharged from the second section hole to achieve recycling. The largest granularity materials like fiber, bamboo & wood, rubber, leather, and metal are discharged from the last section, then enter into the density sorting unit to take further separation.

3. Technical feature of semi-wet selective crusher

① Achieve crushing and sorting in one machine.

② Fully recycle the useful materials in the wastes.

③ Good suitability for the feed materials, easy crushing and discharge timely.

④ Low power consumption, small abrasion, easy maintenance.

⑤ Change the barrel length, crushing section number, mesh size if has special requirement.