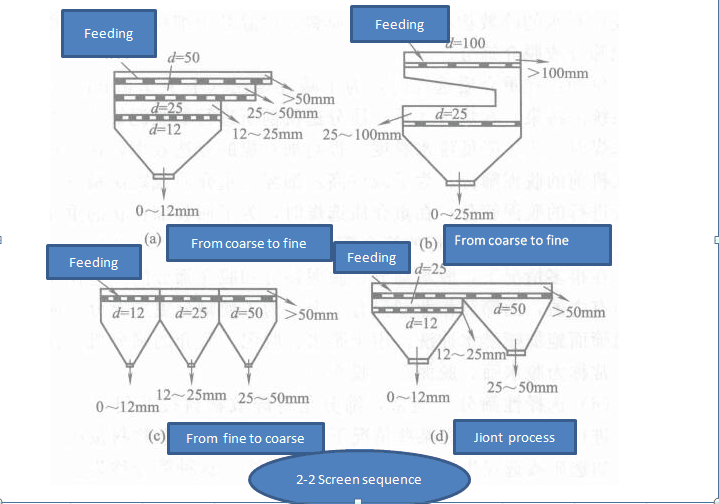

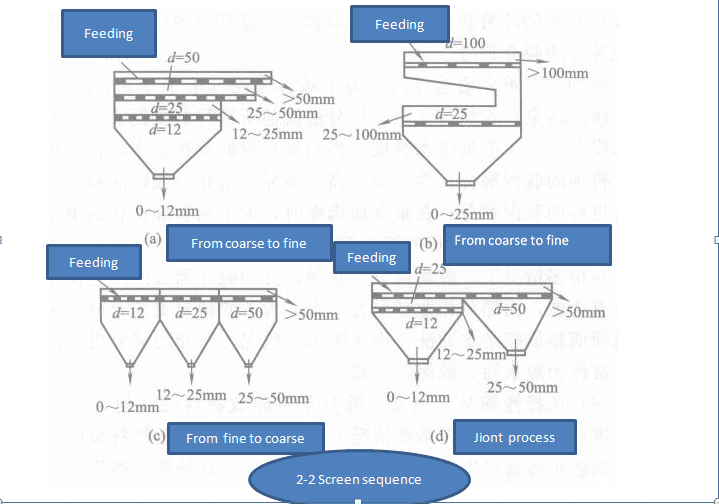

Screening sequence

When the granularity level of crushed material screening product is more than two types, the problem of screening sequence will be appeared. There are several screening orders, as below:

(1) Superposition method

The screening from coarse to fine. In the process of screening flow from coarse to fine, screening surface overlapped one by one, the mesh size of upper screen surface is bigger, the following meshes gradually reduced, as shown in the figure 2-2(a). The advantages of overlapping method process are:

1. The top of the screen surface wear is smaller, all the most of the material and its largest blocked added on the surface of largest screen mesh, but the screen surface is often composed of steel bars, and not easy to be worn, and be able to protect the lower fine-mesh sieve;

2. The screening efficiency of fine-level material is higher, because the material number of adding on the fine mesh surface is less;

3. The crushing that coarse level of material in the process of screening is less, because the coarse material can be separated from the screening process quickly, which is a great significance to the coal screening;

4. Due to the multilayer overlapping of screen surface, the layout of screening device is more compact. The disadvantages of overlapping method process are: it is inconvenient to observe the work situation of lower screen surface. Replacement of the screen surface is difficult and the layout is too dense, the levels of materials just can be discharged from one end of screen. According to the process layout of screen surface in the figure 2-2 (b), the discharge location of all levels can be divided, the bottom part of the upper screen surface is equipped with the screen base, which can add the material to the head of lower screen and improve the efficiency of screening for the lower screen.

(2) Combined method

Mixed screening. In the process of combined, one part of the screen surface shall be arranged from coarse to fine, the other part of the screen surface shall be arranged from fine to coarse, as shown in figure 2-2 (d).In the practice of production, usually use the screening flow from coarse to fine or combined screening flow.