(1) According to action mode of crushing force, crushing machine can be roughly divided into two categories: crusher and grinding machine.

Generally, crusher treats relatively large materials, whose granularities are greater than 8 mm. The structure feature is that there is a gap between its crusher structure, do not contact with each other. Crusher can be divided into the primary crusher, medium crusher and fine crusher. In general, the grinding machine treats fine materials, whose particle size are fine, less than 0.074 mm, and even some fine. The characteristics of crushing parts or medium are contacted with each other, grinding medium is steel ball, steel rods, gravel or ore block, etc. But some mechanical machine has the function of crushing and grinding at the same time, such as the autogenous mill with the diameter of 5.5 x 1.8 m can process ore particle size up to 350-400 mm, the product fineness less than 200 mesh can cover 40%.

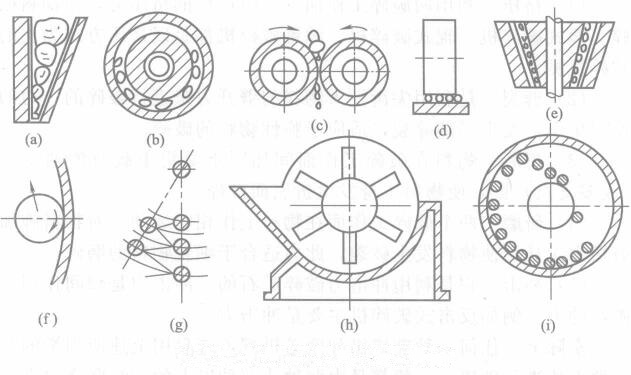

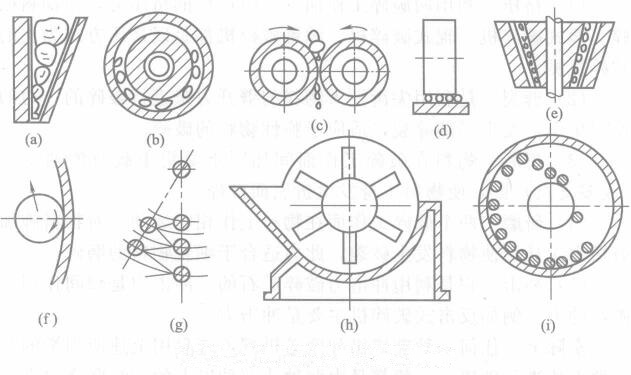

(2) According to the crushing method and mechanical structure (movement principles), crushing machine can be categoried into six kinds, which are demonstrated below:

① Jaw Crusher (a): The crushing principles is to relay on squeezing force, generated by the periodical movement of movable jaw towards fixed jaw plate, to crush the materials in between.

② Cone Crusher and Gyratory Crusher (b): The minterial block is placed between two cones. External cone is fixed, internal cone doing eccentric movement to crusher the material into pieces.

③ Roller crusher (c): Material block is in the space between two rotating rollers that rotate on the contrary directions. The material received continuous compress, at the meantime, it has grinding functions on the material. The tooth on the roller has cutting function.

④ Impact crusher (d)(g)(f): The material received the impact force given by the fast rotating spare parts to crusher the mateiral. Such crusher can also be categories into hammer crusher, cage crsuher and impact crusher.

⑤ Rotary Breaker (e): Rotary breaker is also called selective crusher. It has the functions of crushing and screening and it can achieve the purposes of screening materials. It untilizes the hardness difference of coal and rock, namely it selects matieral according to the impact difference on different materials.

⑥ Ore mill machine (f)(i): Minerial ores rotates in the rotating cylinder that is filled with grinding mateirals such as steel ball, steel bar, gravels or minerial ores. By the impact force and griding force between the mateiral and the medium to achieve the matieral crushing purposes.

⑦ Other kinds of crushing and grinding machine

1. Roller mill, by employing the rotating roller to crush the material.

2. Dish grinding machine, by making use of the dishes that making vertical and horizontal movents to crush the material.

3. Eccentric grinding machine. Using eccentric force that generates from spare part and medium to crush the material.

4. Vibratiing grinding machine. Utilize high frequence generates by spindles to crusher the mateiral with mediums.