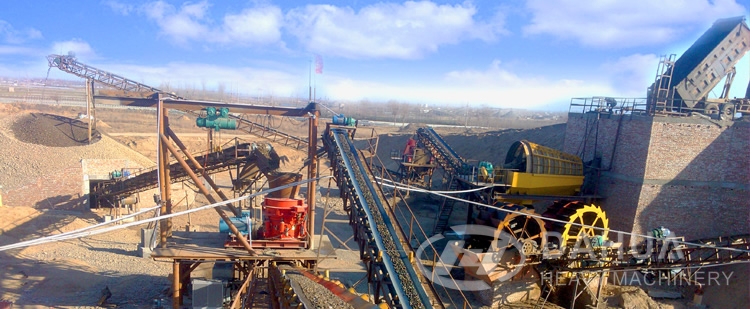

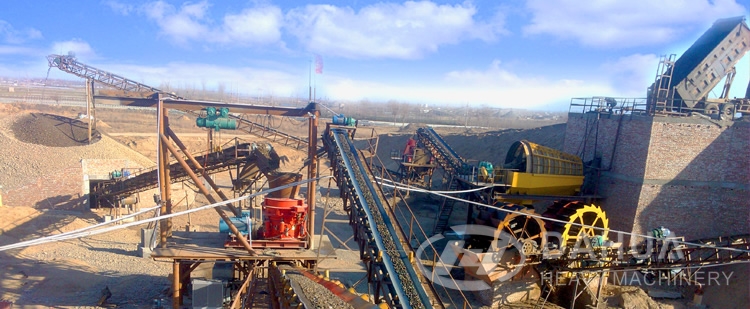

As large-scaled mechanical equipment, the workload of crusher is heavy, the working condition is serious bad, which are easy to cause fault during operation. Therefore, the machine operator should pay attention to the maintenance and repair, know about the factors that influence the machine operation, so as to make sure the normal operation to reduce the losses caused by machine fault. Luoyang Dahua will analyze the factors on affecting the machine operation:

Firstly, during operation, the temperature of each part should in the limit scope, high or low temperature will influence the normal running. In the process of running, one hand is to prevent the crusher taking overload operation under low temperature. Before start the machine, preheat the machine to the proper temperature and then feed materials. The other hand is to prevent working under high temperature. Often check the thermometer, if found the temperature is too high, stop the machine to check.

Secondly, dust, soil and metal filing will influence the normal operation. Once the impurities enter into the machine, they will cause big damage. Not only impede the relative movement, accelerate the parts abrasion, but also scratch the matching surface, destroy the lubrication oil film, enhance the spare parts temperature, and spoil the lubrication oil.

Finally, the chemical substances that contained in the materials, air and rain also can corrode the machine. For this, we can treat the materials in advance to reduce the influence, at the same time, operators should take effective measures according to the weather situation to reduce chemical corrosion.