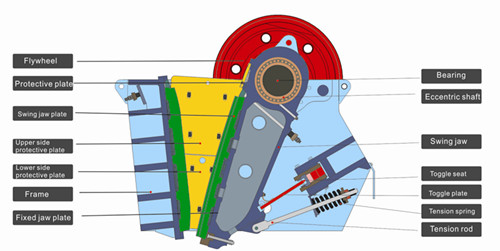

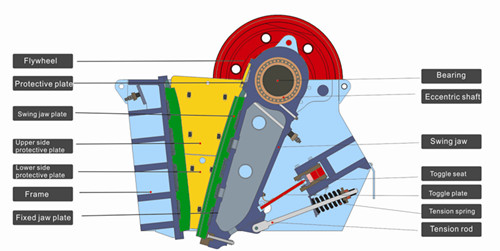

As we all know, jaw crusher is composed of movable jaw plate and fixed jaw plate that simulates the jaw movement of the animal to finish the material crushing works. The movable jaw is both one of the important parts and the larger part in the crushing machine. Its design can determine the final crushing effect, therefore, the manufacturer should start from optimizing the jaw plate design to improve the performance and technology. How to optimize the design of jaw plate? Luoyang Dahua will give you the following solutions:

Firstly, most of the jaw crusher's weight is very heavy, and movable jaw is a part that account for a larger weight. Therefore, under the condition of meeting the strength requirement, we should try to reduce the jaw plate weight as much as possible. The detail method is to use the thickened strengthening rib, means the top strengthening rib (header) should be thin, the more thick the bottom rib. That is to say, change the original rectangle strengthening rib to the trapezoid strengthening rib, which can reduce the movable jaw plate weight and ensure enough strength.

Secondly, strengthen finite element research on the frame and movable jaw plate to achieve light weight and high reliability of frame and movable jaw plate. Furthermore, use computer to optimize crushing cavity and dynamic balance of crusher. In a word, we should utilize modern design method to replace the original conventional design method.

Finally, welding and casting process also influence the jaw plate and the whole machine's performance and quality, so enhance welding technology is very necessary.