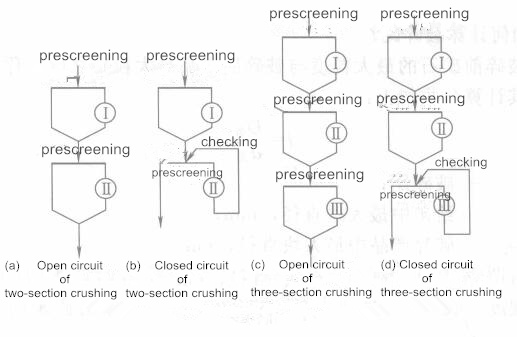

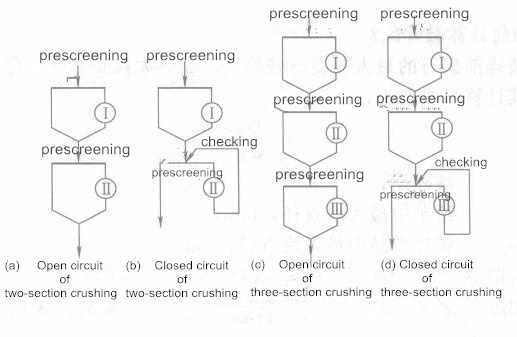

The common crushing section at ore dressing plant is two-section crushing and three-section crushing.

Two-section crushing includes open circuit crushing 【Figure-1(a)】and closed circuit crushing【Figure-1(b)】. The secondary crushing section of the latter one and the check screening together form a closed circuit, which ensures the products granularity meet the requirement, not to influence the next grinding process. Two-section crushing only suitable for the small mine that used underground mining. The crushing ratio is around 15-25, and the crushing amount is 1000t/d.

Open circuit of two-section crushing is rarely used, which is used only in reselection plant, and then convey the crushed materials to the rod mill or jigging. Most of the dressing plants adopt closed circuit crushing.

Three-section crushing also includes open circuit crushing 【Figure-1(c)】 and closed circuit crushing 【Figure-1(d)】. From the figure, we can see that before each crushing section, there is prescreen process, or do not use prescreen at the first and secondary crushing section. The open circuit of three-section crushing can not ensure the final grain size meet the requirement, so it is rarely used. At closed circuit of three-section crushing, adopting check screening at the third crushing section to form closed circuit, which is the most common circuit. Three-section crushing is suitable in large, medium and small dressing plant, its crushing ratio is up to 25-200mm, the max. feeding granularity is up to 1000mm, the crushed granularity is 12mm or less.

In individual cases, when the size of dressing plant is large, and the raw materials are big, in order to reduce the crushing ratio in each section or in order to get finer particle size, we can use four-section crushing circuit.