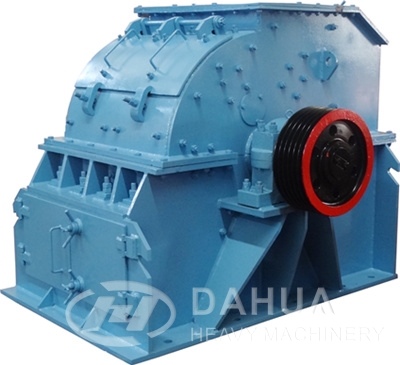

As a kind of important crushing machine, hammer crusher is popular for its large crushing ratio, high production capacity, low energy consumption, simple structure and even particle size. The suitable and good crushing equipment can bring benefit for the customer, but if we do not maintain or repair properly during operation, it inevitably cause unnecessary loose for the enterprise. Therefore, it is necessary to take correct maintenance and repair.

1. Daily maintenance and repair include the cleaning of equipment; check the machine components and parts, especially the key wearing parts; check the screw are fastening or not, and the lubrication system;

2. Equipment lubrication is an important work in daily maintenance and repair, so it is important to select the suitable lubrication material. Currently, the main lubrication materials are lubrication grease and lubrication oil that should be selected according to the customer site situation.

3. To ensure the operator has the professional quality and the operational capacity.