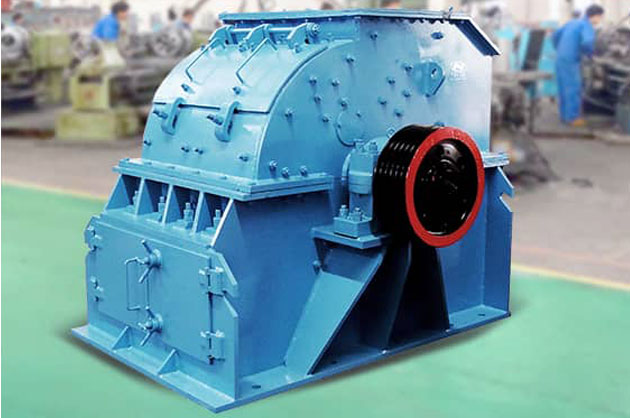

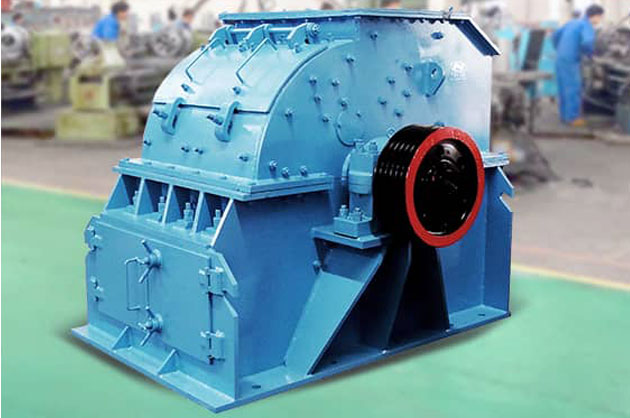

Hammer crushers are widely used in the mining machinery industry. Due to their superior crushing performance, the hammer crusher is driven by a motor to rotate the rotor at a high speed, and the material enters the crusher cavity evenly and rotates at a high speed. The crusher’s hammer head impacts, shears and tears the material, causing the material to be broken. It can be seen that the hammer head of the crusher is one of the main components of the hammer crusher, and its wear is also serious. So, how to reduce the wear of the hammer head and increase its service life? Luoyang Dahua has summarized five ways to extend the life of the hammer crusher.

- Frequently adjust the internal clearance of the hammer crusher. In the process of use, the gap of each part must be adjusted frequently to make it within the proper range. In this way, there will be no accumulation of material, the wear of the hammer head of the crusher will be reduced, and its life will be increased.

- Reasonably formulate the technical parameters of the hammer crusher. The technical parameters of the hammer crusher will affect the life of the hammer head, mainly the power and speed of the rotor. They not only affect the production capacity of the equipment, but also affect the degree of impact hardening of the hammer. If the impact hardening degree of the hammer is maintained well, its service life will be prolonged.

- Choose a good hammer material. The material is the core factor that solves the wear resistance and service life of the hammer head of the crusher. Therefore, when choosing a material, choose a material with good quality, high wear resistance and strong flexibility, which will help increase the service life of the crusher’s hammer.

- Fix the hammer head of the crusher. In the process of impact between the hammer head of the crusher and the material, if the hammer head of the crusher is not fixed properly, it may cause the hammer head of the crusher to fly away from the rotor and cause damage to the hammer head of the crusher. Therefore, the hammer of the crusher must be fixed during installation to extend the life of the hammer of the crusher.

- Regularly clean the accumulated material in the crushing cavity. If too much material accumulates in the crushing cavity, it will cause serious wear and tear on the hammer head of the crusher, thus reducing the service life of the hammer head of the crusher.

The above is the method to improve the service life of the crusher hammer provided by the majority of users and friends of Luoyang Dahua. I hope to help the majority of users and friends. If you want to know more about the wear-resistant parts of the crusher, you can call my service hotline or online consultation.