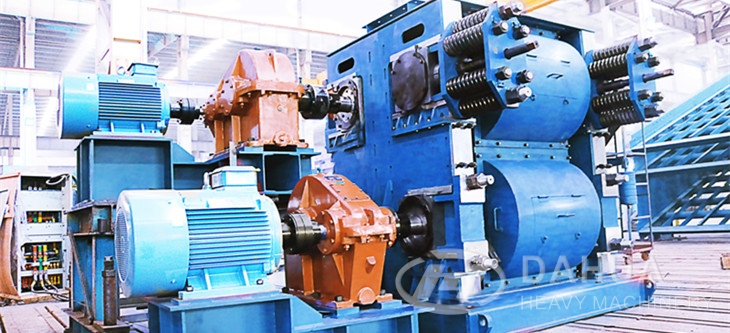

Test of Double Roller Crusher

After installing the machine completely, it can start test If no problem after non-loading test for 4 hours, then the loading test can be started

After installing the machine completely, it can start test If no problem after non-loading test for 4 hours, then the loading test can be started

Gyratory cone crusher is one kind of coarse crushing equipment, which has been widely used in mining, metallurgy, chemical concentrator

Bearing is a major component of the crusher, its performance directly influence working condition of whole equipment If bearing is not well maintained, this could lead to crusher breakdown

As we all know, during the usage of jaw crusher, jaw plate is the most easily wear out component, Hence, how to prolong the service life of jaw plate is of great importance

With the coming of winter, the temperature keeps low, so we need to take all the necessary measures and make thorough inspection and maintenance of the equipment to make sure the machine can go through the winter safe

In this text, Luoyang Dahua will talk about the roles of lubrication oil on cone crusher

Mechanism sand is a new building material that develops with the application of infrastructure building sand Sand making machine has already become one of the fine crushing deep processing machine, which has important development significance for new type urbanization

Jaw crusher has some advantages such as large crushing ratio, simple structure, easy maintenance, low production cost, large output, wide application range and etc

In this text, Luoyang Dahua will talk about the precation before installation pf double roller crusher

Jaw crusher is composed of movable jaw plate and fixed jaw plate that simulates the jaw movement of the animal to finish the material crushing works