How to configure A Cost-Effective Mobile Stone Crusher Station?

wheeled body or caterpillar chassis. The whole configuration is reasonable, structure is compact and flexible.

wheeled body or caterpillar chassis. The whole configuration is reasonable, structure is compact and flexible.

Jaw plate, also called tooth plate, is the key wear - resistant parts in jaw crusher. A set of jaw plate is usually composed of two parts, namely moving jaw plate and fixed jaw plate.

ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.

VSI crusher, that is a vertical shaft impact crusher, can be used for most crushing and sand making applications. The VSI sand making machine will be used in quarries and gravel pits to produce products.

Stone cone crusher has large crushing capacity, which is used for the crushing of hard materials, like granite, iron ore, steel slag, and refractory material, etc.

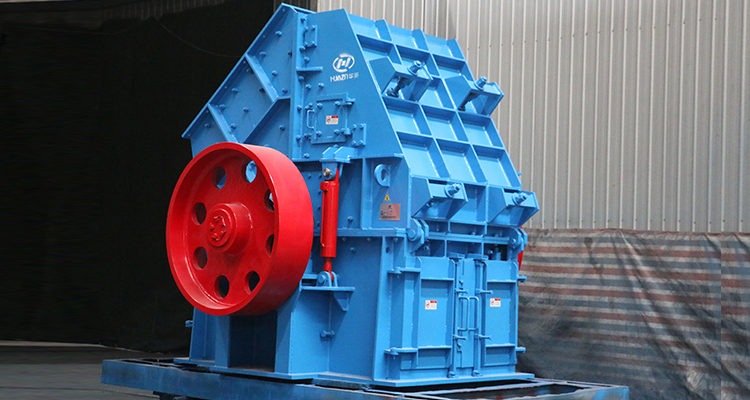

Granite crusher plant has two types: fixed crusher machine and mobile crusher plant. The fixed granite crusher machine includes granite jaw crusher, granite cone crusher, hammer crusher.

Speaking of which crusher is more advanced, there is no need to say more, mobile gravel crusher is worthy.

Mini hammer crusher is suitable for the fine crushing of medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, combustion and other industries.

Due to different types of crusher machine can complete the production need of different materials, it is necessary to choose the appropriate type of equipment according to the nature of materials when investing in sand production line.

The price of granite crusher is decided under the influence of many factors, such as the size of equipment model, sales mode and the nature of the manufacturer.