The autogenous mill is a type of ore grinding equipment that combines crushing and fine grinding functionalities. It utilizes the material being processed as a grinding medium, achieving comminution through mutual impact and abrasion.

The autogenous mill is a type of ore grinding equipment that combines crushing and fine grinding functionalities. It utilizes the material being processed as the grinding medium, achieving comminution through mutual impact and abrasion. Autogenous grinding allows for the direct feeding of large-sized ores, with maximum dimensions ranging from 300mm to 500mm, into the mill. Due to the motion of the ore chunks within the mill resembling that of media in a ball mill, the ore particles are subjected to both grinding and intense impact, resulting in efficient size reduction.

The most significant characteristic of an autogenous mill is its ability to process raw materials directly from the stope or primary crushed ore. Typically, materials are introduced into the rod mill based on their particle size distribution. The autogenous mill can grind materials to a fineness of less than 0.0744 mm, with this fraction comprising between 20% and 50% of the total output. The reduction ratio can achieve up to 4000-5000, which is over ten times higher than that of ball and rod mills.

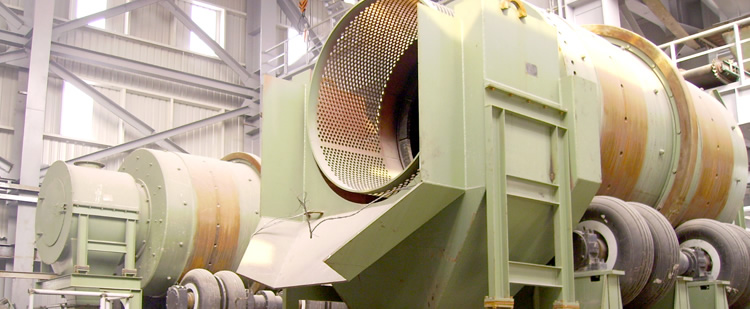

The structure feature of autogenous mill:

(1) The autogenous mill features a large diameter and short length, resembling a flat drum. The ratio of length to diameter (L/D) is approximately 0.3 to 0.35. Since the ore itself serves as the grinding medium, the “segregation” phenomenon that occurs during grinding can reduce the operational efficiency of the mill.

(2) The large diameter of the hollow pivot at both ends of the barrel body is designed to accommodate the size of the fed ore.

(3) The central section of the barrel liner in the wet-type autogenous mill is designed with a concave profile to prevent segregation of the crushed material particles.