Fault Reason of No-load Test of Jaw Crusher and the Solution

Before jaw crusher put into production, the customer needs to take no-load test to check the crusher

Before jaw crusher put into production, the customer needs to take no-load test to check the crusher

Hammer head is a kind of wearing part of impact crusher with large consumption, so enhance the service life is always the pursuit target for the customer

After repairing and maintaining of cone crusher, following is no-load test for 2-6 hours If there is no problem, could proceed the next operation What are the requirements of cone crusher? Let s have a look

During working process, the crushing plate directly contacts with the materials that receiving large crushing force and material friction It service life has close relationship with the working efficiency of jaw crusher and production costs

Jaw crusher is the common crusher in the crushing device It has large advantages in the material selections and crushing scope In what aspects does the advantage embodied?

Complex crusher plays an important role in the sand making production line If some problems appeared in the process of operation, the whole production line cannot produce normally

During production, if the spindle head lose efficacy it will influence the production schedule, or even scrap the bearing component In daily production, how to prevent this situation? We could start feom the following aspects

If the impact crusher s grid plate is damaged, it seriously influences the products granularity and the production efficiency Aimed at this problem, we will introduce the damage reason and prevention method for the grid plate

There are many kinds of spring types, they are classified according to the different standard Here, this text will introduce the types of spring

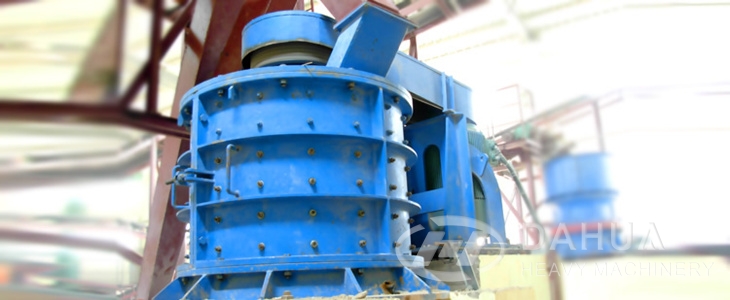

In this text, we will talk about the features of PFQ vortex strong impact crusher