The market

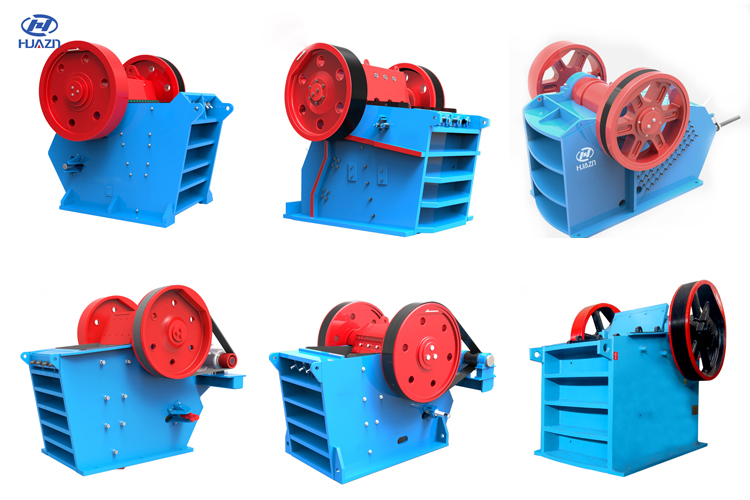

In recent years, due to the strengthening of environmental awareness and the severe ecological environment, the exploitation of natural sand has been exhausted, and the government has increased the control over mining. The supply and demand of aggregates and aggregates in the national economic construction are not balanced, and natural sandstone is in short supply. Under such a background, the development of mechanical sand with stable output and quality can not only solve the contradiction between the imbalances of supply and demand of aggregates in the national economic construction, but also effectively solve the problem of sand for construction. Moreover, the mechanism sand is more controllable than the natural sand, the mechanism sand type is controlled, and the supply is stable. According to different use sites, the sand making parameters can be adjusted, and different grades of finished sandstone can be harvested, which makes the mechanism sand very popular in the market. The "machine" in the machine sand refers to the crusher. Generally, the mechanical sand needs a broken, broken, sand making machine, and of course some supporting machines are needed. This “one break” usually refers to the jaw crusher, which is used to crush large materials, and then sieved into two broken (impact crusher, cone crusher). After screening, the particle size conforms to the sand making machine. Request to enter the sand making machine. In general, the prospect of jaw crusher is still very good.

Price quotation

What is the price of an efficient jaw crusher? This is mainly determined according to the user's actual choice, because different manufacturers, different models, different time points, etc., the equipment offer is different.

1. Different manufacturers, different prices

The price of the user who chooses the equipment is different, and the price is definitely different because different manufacturers have different technologies, processes, raw materials and time, so the price of the equipment is different.

2. Different models, different prices

We all know that there are many models of high-efficiency jaw crushers. The high-efficiency jaw crushers of different models and specifications have different daily output, different production efficiency, etc., so the price of the equipment is different, but the price is different. It is recommended that users choose the right type of equipment according to their actual production needs, which can make the equipment run more stable and reliable.

3. Different time, different prices

The price of equipment purchased at different time points may also be different, because the price of raw materials used by different equipment at different time points will also fluctuate up and down, and the preferential policies of manufacturers at different time points are also different, so the price will also fluctuate.

Investment prospects

1. The cost budget is not high:

(1) Jaw crusher sand and gravel sanding materials are sufficient, as long as there is a place where stones can produce machine sand, and, where conditions permit, urban construction waste and mine tailings can also be used to develop mechanical sand materials, so The raw material cost budget of the jaw crusher is not too high compared to the acquisition of natural sandstone at a high price;

(2) In the current market, manufacturers of jaw crusher equipment, in addition to consignment manufacturers, there are also some direct-selling manufacturers. The price of jaw crushers given by them is the factory price of the value, so in general, the selection the cost budget of the hopper crusher is not too high.

2. Large market demand:

(1) Sand and gravel is one of the important raw materials for infrastructure construction in China. In the current market where natural sandstone is gradually depleted, it is possible to produce artificial sandstone sanding equipment comparable to it, and the market demand will not be less;

(2) The size of the gravel material after sand treatment by the jaw crushing mechanism is adjustable, which can meet the different production needs of different users at present, so the multi-denature jaw crusher will be more popular than the natural sandstone;

There are many manufacturers on the market. When purchasing equipment, users should choose the strong sorghum crusher as the manufacturer. The general strength of the manufacturer is excellent in equipment quality, good performance, perfect after-sales, and factory direct equipment. The price is relatively low.

For more information, you can click: www.lydhchina.com