In the current environment where natural sand and gravel are banned, machine-made sand will replace natural gravel aggregates on a large scale. In the construction industry, the sand-making process is particularly important. How to choose the right sand making process according to your own situation?

First of all, we should understand the main sand making processes, including dry sand making, wet sand making, and dry and wet sand making. These three are commonly used in sand making.

Secondly, we need to grasp the difference and application situation between them:

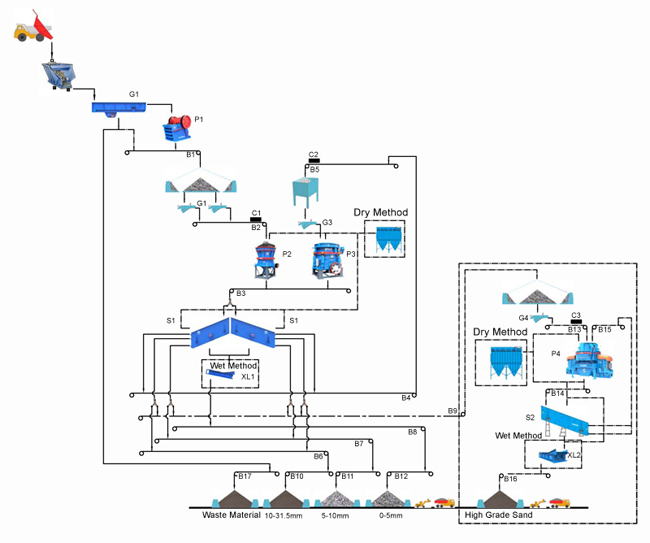

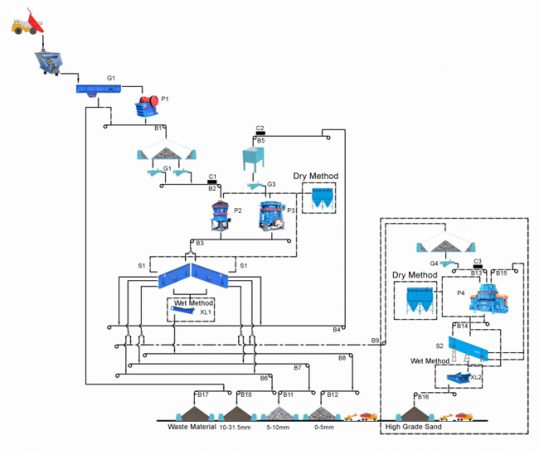

- From the name of dry sand making, we can clearly see that this sand making process does not require much water and is suitable for areas with relatively arid and low rainfall. The specific processing flow of dry sand making is: raw materials -> vibrating feeder (remove soil waste) -> coarse crushing -> medium and fine crushing -> sieving (screening large aggregates) -> sand making -> sieving (sieve) divided into small aggregates) -> dust removal -> powder selection -> finished sand. When discharging, the content of stone powder in the machine-made sand can be adjusted by the classifier to make it meet the standards of urban construction and hydropower engineering, and it is used in construction engineering, railway and other departments. The fine powder produced can be recovered by dust removal and powder separator, and used for road cushions or raw materials for slag bricks. It can be seen that dry sand making can make full use of the finished products.

- The general process of wet sand making and dry sand making is the same, except that a lot of water resources are needed in the sand making process. Therefore, wet sand making is more suitable for rainy and water-rich areas. The specific processing flow of wet sand making is: raw materials -> vibrating feeder (remove soil waste) -> coarse crushing -> medium and fine crushing -> sieving (screening large aggregates) -> sand making -> sieving (sieve) divided into small aggregates) -> sand washing machine -> finished sand. Compared with dry sand making, you will find that they have only a slight difference in the processing flow, that is, the sand washing machine replaces the powder separator and the dust collector. In this process, a lot of water resources are needed, and there is no dust pollution in the production environment. The finished product is also cleaner and of better quality, but the output is lower.

After understanding the first two sand making processes, the dry and wet integrated sand making process is basically clear. That is, the dry sand making and wet sand making are combined, and the aggregate is washed during the previous screening, and the finished sand part no longer passes through the sand washing machine. This processing technology also requires a certain amount of water resources, and the costs of sand making is higher than that of dry sand making and lower than that of wet sand making. According to the characteristics of the three sand-making processes we know above, when we choose the sand-making process, we choose according to the requirements of our region, water resources, raw materials, and discharge, but from the environment and cost. In terms of consideration, the dry method is generally preferred, followed by the dry and wet integrated and wet sand making. Water resources are a relatively scarce resource in our country. If the content of source soil and organic matter can be controlled, the finished sand produced by dry sand has low water content and high output, and is not affected by seasonal factors. It is a very popular method for sand production sand craft. You can consult in detail if you have any questions about sand making.