After a lot of application practice, we know that the mechanism sand made of high hardness rock, such as granite, pebble stone, basalt and other stone materials can meet the standard of high quality construction sand, suitable for many large-scale engineering projects, and bring more benefits to sand production users. In this article, Luoyang Dahua Heavy Industry engineer will introduce how to choose the hard stone crusher for 200 t/h sand making production line. Although it is 200t/h for example, the mentioned crusher equipment have reference value in 50t/h, 100t/h, 500t/h, and 1000t/h production line.

What are the crushing equipment which can produce 200 t/h for hard rock sand making?

In general, the three-stage crushing process is adopted for hard rock sand making, namely, coarse crushing, medium crushing, and fine crushing. The required equipment is selected according to the production capacity, raw material granularity, discharge requirements and working ways. The recommend stone crusher equipment is jaw crusher, cone crusher, fine jaw crusher, roll crusher, sand making machine, and mobile crusher plant.

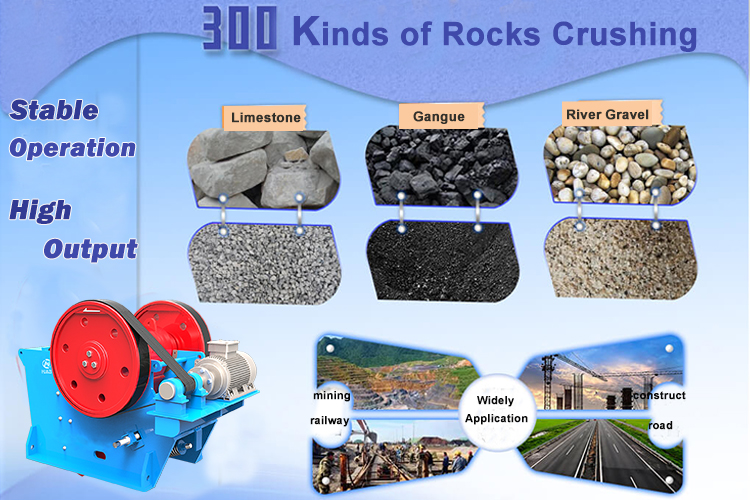

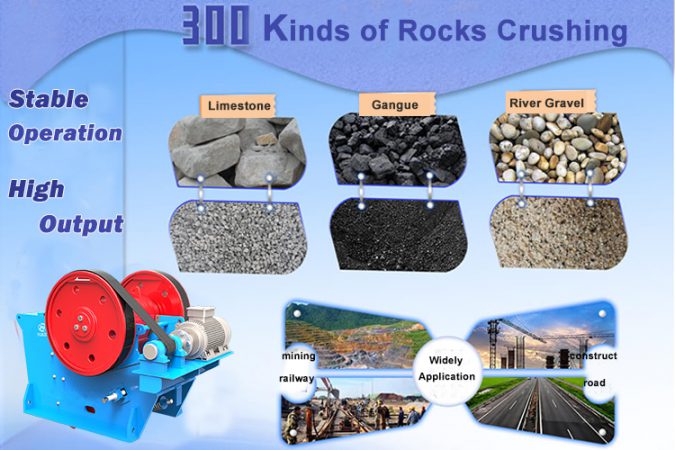

◈ Jaw crusher: V-type deep crushing chamber, processing of large raw material and the throughput is large. This jaw crusher can process the material stably, simple operation, and more durable. JC series jaw crusher is commonly used for rough crushing, and DHKS series jaw crusher is relatively small in size, which is suitable for the secondary crushing after rough breaking.

◈ Roller crusher: the discharge particle size is between 2-10mm, which means that some specifications of coarse sand and gravel can be made, and it is outstanding in the production of pebble sand. Roller crusher is suitable for the use of small and medium-sized stone factories with capacity less than 300 t/h.

◈ Cone crusher: crushing cavity, mantel, high manganese steel lining and other vulnerable parts can provide greater crushing force, very suitable for processing high hardness material like granite, with the advantages of high efficiency and large capacity.

◈ Sand making machine: the discharge particle size is 0-5mm, which has the characteristics of uniform discharge, good shape of finished particles and low comprehensive consumption. It is commonly used to making sand in the production process of hard rock sand making production line. Sand making machine cooperates with the sand washing machine to improve the purity of sand, so as to meet the requirements of high-quality construction sand.

◈ Mobile crusher plant: A crushing equipment not confined to the site, such as roads, tunnels, Bridges and other engineering projects need to follow the progress of the project to move at any time. It is more suitable to use mobile crusher plant. The equipment can carry a variety of crushing equipment, strong adaptability, simple operation, easy to control the program, convenient and fast.

The above introduce the main crushing equipment used in hard stone sand making. In addition to these, vibrating feeder, vibrating screen, belt conveyor and other auxiliary equipment are also indispensable in sand making production line.

Luoyang Dahua Heavy Industry is a well-known manufacturer of crushing and screening equipment in China. We provide customers with a full range of crushing and screening equipment. We not only provide customers with high quality products, but also provide first-class service support and solutions. Welcome the customer contact us!