With the growing demand for large-scale infrastructure, a wave of investment in sand-making machine production lines has swept through the industry. Choosing the right configuration for a 30 t/h aggregates sand making production line is an important consideration. In this article, we will introduce the configuration and process of a 30 t/h sand making production line for you.

A complete aggregates sand making production line involves the coordinated work of multiple devices to crush and process stone materials according to production requirements. If you’re aiming to produce high quality sand and gravel aggregates , selecting the right crushing machine becomes important. The 30 t/h sand making production line includes feeding machine, screening machine, crushing machine, sand making machine, and sand washing machine. Among these, the crushers, sand making machine, and sand washing machine are the core equipment of the system.

Crushing equipment

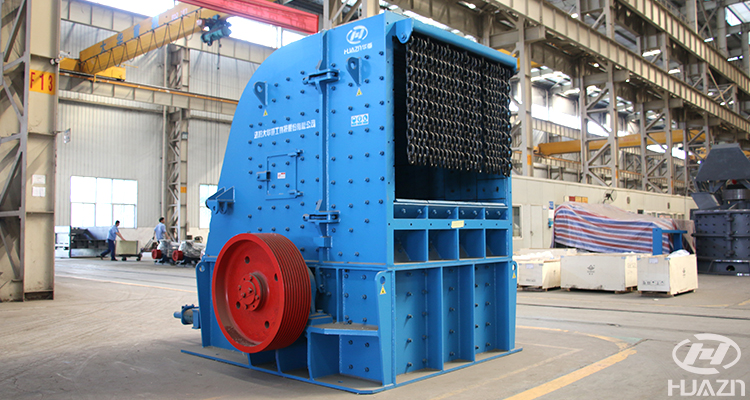

Equipment types: jaw crusher, impact crusher, cone crusher, hammer crusher

Jaw crusher: Jaw crusher is used for the primary crushing of large stones, making it easier for further crushing and sand making process. The machine has large feed opening, a deep V-shape crushing chamber with a deep feeding cavity, ensuring that large stone can be processed smoothly without splashing. The crushing action is achieved through the combined force of biting, friction, and compression between the movable and fixed jaw plate. The output particle size can be adjusted according to requirements. Additionally, the machine is designed to produce less dust and noise during operation.

Impact crusher: Impact crusher is used after jaw crusher for fine crushing of stones. It is suitable for the crushing of medium-hardness stones. Using impacting force, the impact crusher efficiently breaks and processes the material, resulting in fewer needle-shaped or flaky particles, better grain shape, and high overall efficiency. It is an ideal choice for producing high quality sand and gravel aggregates for construction.

Cone crusher: Cone crusher is also worked with haw crusher to achieve finer crushing of stone materials. The laminating crushing principle of cone crusher can easily break hard stones. Designed with intelligent PLC control, it allows for easy operation through remote control. It has large production capacity, high crushing efficiency, which reduces labor costs.

Hammer crusher: Hammer crusher is a device that offers three crushing effects: coarse, medium, and fine crushing. It features the advantage of one-stop crushing and shaping, eliminating the need for secondary crushing. This means it can directly crush stones and produce ans in a single operation. Compares to other models, hammer crusher reduces production costs. A single unit can support a full sand making production line. It is an excellent choice for users looking foe efficiency and convenience.

Sand making machine

Equipment types: vertical shaft impact sand making machine, sand washing machine

Vertical shaft impact sand making machine: It is an essential equipment for sand making. When used together with coarse and fine crushing equipment, it can produce machine-made sand with a particle size adjustable between 1-5mm. The output particle size is uniform, the shpe is good. Sand making machine also has the advantage of stone shaping. It is specially designed for producing high quality construction sand.

Sand washing machine: sand washing machine is typically used together with sand making machine to clean the machine-made sand and remove impurities. It can remove stone powder, impurities, and small stones from the finished products, thereby enchaining the quality of machine-made sand. The bucket wheel sand washing machine is commonly used in production line due to its compact design, excellent cleaning performance, and the ability to recycle and reuse the water used during the cleaning process.

Quotation for 30 t/h aggregates sand making production line

The price for a 30 t/h sand making production line is relatively inexpensive, for details quotation, please contact Online Service. Luoyang Dahua can offer you free design for 30 t/h sand making production line, including tailored configuration plans and equipment selection. Our factory features dedicated production workshops with mature processing technologies and advanced manufacturing process. With a large, standardized workshop space, we provide a wide range of sand making equipment, from fixed to mobile models, ensuring that all necessary equipment models are available for each production line.