Pebble stone is a type of natural stone, which is the ideal material for constructing courtyards, roads, and buildings. The sand produced by river pebbles has superior quality compared to natural sand. It not only enhances the quality of building materials but also meets high standards for building sand. Let’s now have a look at the production line for 50 t/h pebble stone sand processing.

Equipment configuration for 50 t/h pebble stone sand making production line

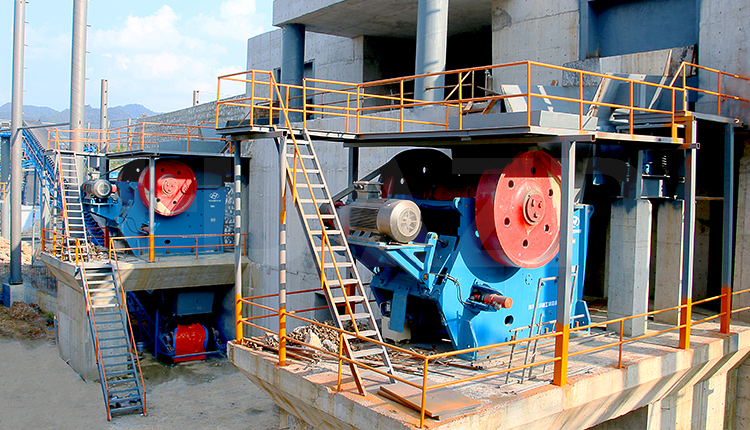

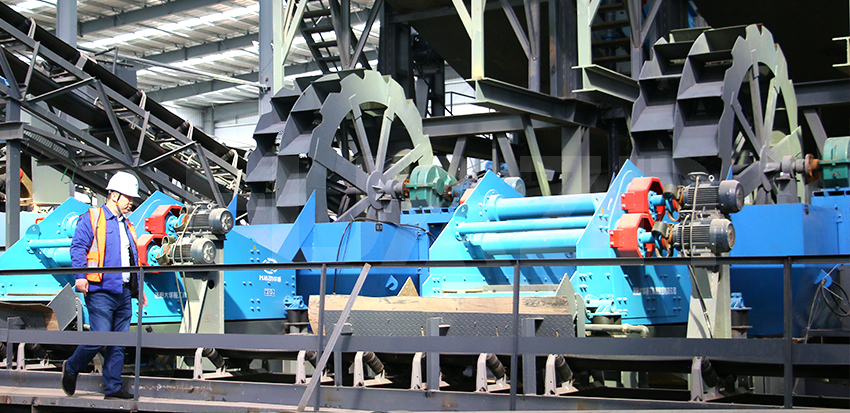

In the production line of pebble stone sand making, the pebble sand making machine is specifically designed for processing river pebbles. The finished materials have uniform particle size and high compressive strength, ensuring consistent quality. Furthermore, it is equipped with a vibrating feeder, a fine jaw crusher, a sand washing machine, a circular vibrating screen and other auxiliary equipment.

Vibrating feeder: ZSW vibrating feeder can be selected to provide a continuous supply of feed, ensuring the normal operation and production efficiency of crushing equipment.

Jaw crusher: The fine jaw crusher is utilized as the primary crushing equipment for river pebble, while the river pebble sand making machine is directly applied for secondary crushing. It is recommended to select a fine crushing crusher to break large pieces of river pebble into 30-35mm particle size, which can be used directly for secondary sand making.

Pebble sand making machine: choose the PLS sand making machine produced by our company, which realizes the free conversion between “stone beat stone” and “stone beat iron”. The finished product has excellent particle shape and reasonable grading, improving production efficiency. It is especially suitable for artificial sand making and stone shaping.

Sand washing machine: The DXS sand washing machine is chosen to clean finished materials in accordance with the wet sand making production line process, ensuring that its cleanliness meets national standards for sand production.

Circular vibrating screen: the YKR series vibrating screen can be selected for screening materials from a jaw crusher. Its main purpose is to separate qualified and unqualified materials, with the former being sent to a river pebble sand making machine for further processing while the latter are returned to the jaw crusher for additional crushing.

With a development history of 60 years, Luoyang Dahua specializes in the production of crushing and grinding equipment. Our products have obtained ISO9000 certification, ensuring reliable quality. With rich experience in equipment selection and production line design and construction, we provide production line design services to over 200,000 customers worldwide. For more information about our crusher machines, please feel free to contact us at any time.