Sand and stone demand is large, natural sand is sharply reduced. The artificial sand making production line can crush the rock into sand that meets the standard of sand for use, which can be used instead of natural sand to relieve the scarcity of sand and stone. Today Luoyang Dahua engineer introduces artificial sand making process and machine for your reference.

I. What is the process of making sand?

Artificial sand making production line can be divided into dry sand making and wet sand making. The main difference between the two is whether to use sand washing machine. The following describes the production process of artificial sand making.

1. Dry sand making process

Dry sand making process is improved based on the traditional wet sand making process. The produced sand aggregates do not need to be cleaned by sand washing machine. After being screened by the vibrating screen, the qualified sands are directly sent to stock pin. The wet sand making process is suitable for the place where far from water resource.

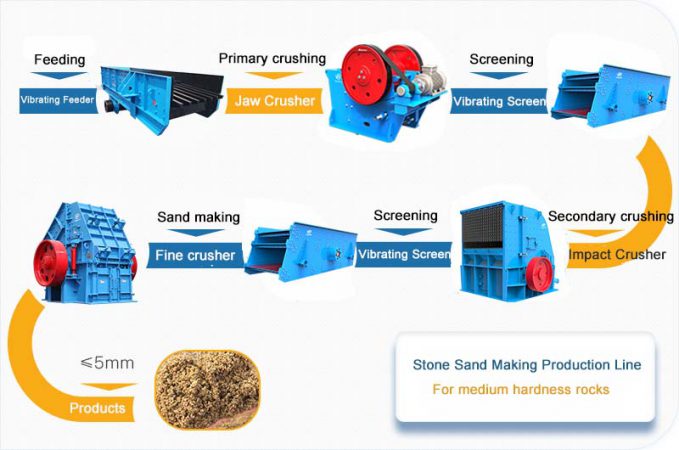

Dry sand making production line process: raw material — feeder — jaw crusher (coarse crushing) — cone crusher/impact crusher (medium and fine crushing) — sand making machine (sand making) — vibrating screen (screening) — finished product pile

2. Wet sand making process

In the process of stone processing, due to the fierce collision or the certain soil content of the stone itself, the artificial sand produced contains stone powder, which affects the quality of sand and stone. In order to avoid this problem, the sand washing machine is equipped to clean and remove impurities from the finished sand and stone, so that it can meet the standard of construction sand. The water consumption is large, and it is suitable for places close to the water source.

Wet sand making production line process: raw material — feeder — jaw crusher (coarse crushing) — cone crusher/impact crusher (medium and fine crushing) — vibrating screen (screening) — sand making machine (sand making) — sand washing machine (cleaning) — finished product pile

II. What are the configuration equipment of artificial sand making production line?

Artificial sand making production line is mainly equipped with crushing equipment, sand making equipment and sand washing equipment. Jaw crusher, cone crusher and impact crusher are common crushing machine. Impact sand making machine is commonly used sand making equipment, and sand washing machine is sand washing equipment.

1. Crushing machine

- Jaw crusher: first-stage crushing equipment, coarse crushing of materials. Jaw crusher has simple structure, large output, small footprint, and high crushing efficiency.

- Cone crusher: two-stage crushing equipment, used for pebble, granite, basalt and other materials with large hardness. Cone crusher has good wear resistance, long life, low production cost, energy saving and environmental protection, mostly used in large sand and stone factory.

- Impact crusher: two-stage crushing equipment, medium and fine crushing of limestone, dolomite, coal gangue and other materials with small hardness, low investment cost, adjustable particle size of finished materials, good grain shape, and small footprint.

2. Sand making equipment

- Impact sand making machine: At present, there are three series of commonly used send making machine in the market: PLS, VSI and PFL sand making machine. The crusher machine with high production efficiency, high degree of intelligence, stable and reliable operation, and both with shaping function. The output of sand and stone particle size is uniform, reasonable grading, good grain shape, the machine sealing is also better, not easy to produce dust pollution. The adoption pf special motor makes the sand making more energy saving and environmental protection.

3. Sand washing machine

- Bucket wheel sand washing machine: there are many types of sand washing machine, the commonly used is bucket wheel sand washing machine. This machine is a new kinds of sand washing machine with relatively high efficiency, high cleanliness, reasonable structure and large output. It is mainly used for washing, classification and dehydration of artificial sand, stone powder, mountain sand and river sand.

At present, there are many kinds of process flow of artificial sand making production line in the market, but most of them meet the characteristics of high degree of automation, low operating cost, high crushing rate, energy saving, large output, less pollution and easy maintenance. For equipment with different capacity demand or finished product demand, the price is different. But in order to make the production of artificial sand in line with the national construction sand standards, we still need to take the production demand as the primary basis for selection.